-

Amelia Brooker

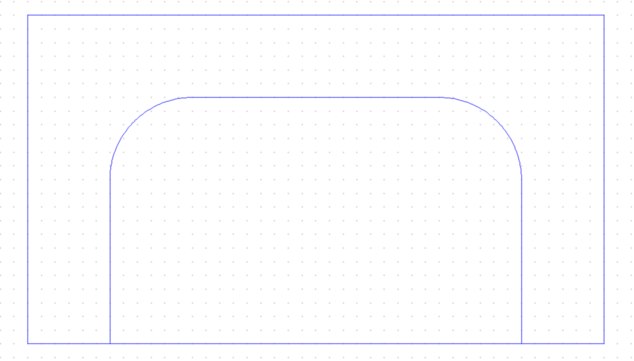

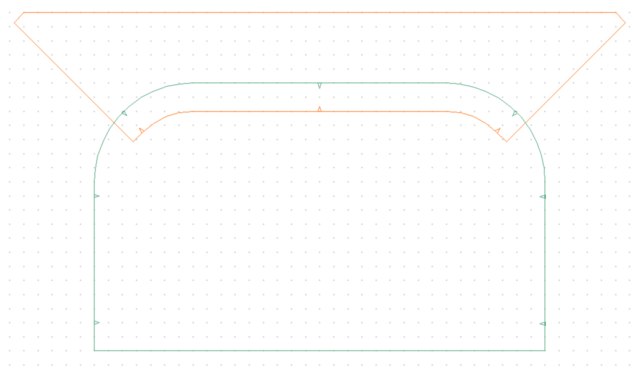

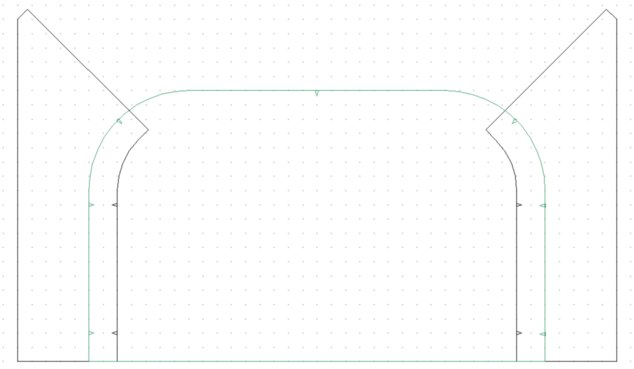

5Hi all! I'm working on a seat for a 32 ford coupe. I'm trying to sew two rounded inserts into the seat. For some reason I'm struggling with this, although I've done it before without issue. It's not sewing in evenly, as you can see in the pictures.

Amelia Brooker

5Hi all! I'm working on a seat for a 32 ford coupe. I'm trying to sew two rounded inserts into the seat. For some reason I'm struggling with this, although I've done it before without issue. It's not sewing in evenly, as you can see in the pictures.

Does anyone have any tips for this? Or can you see what I'm doing wrong?

-

Steven M

3The trick I've learned is you need to offset the outside band's radius by your seam allowance. I'll use 1/2" to make it easy. So you have a 3" radius seam. The insert will be 1/2" larger. The band will also 1/2" larger. This means there's 1" total overlap (2 times the seam allowance) between the two pieces. I find it works well to use staples to hold everything together while you sew it, if you are having problems with it all lining up. -

Cody Lunning

39@Steven M I have issues with this also, can you post some pics sometime? I’m a visual learner and not sure I understand your explanation.

Cody Lunning

39@Steven M I have issues with this also, can you post some pics sometime? I’m a visual learner and not sure I understand your explanation. -

Steven M

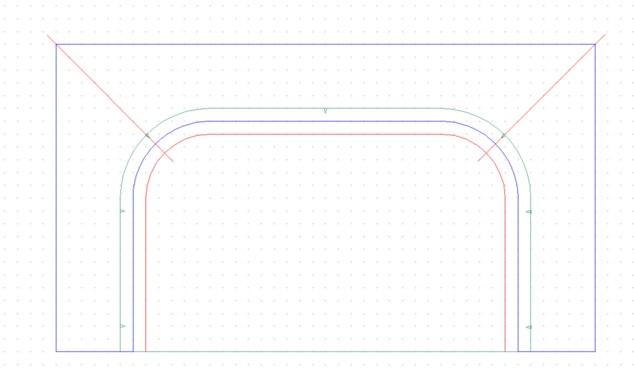

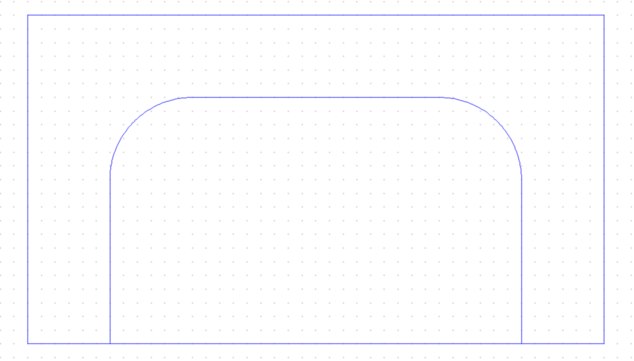

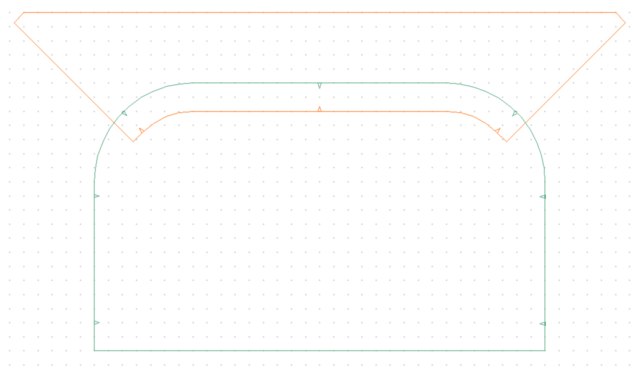

3For stuff like this, I find it much faster to draw it in CAD and cut chipboard patterns on the laser. For this example the blue is the seam:

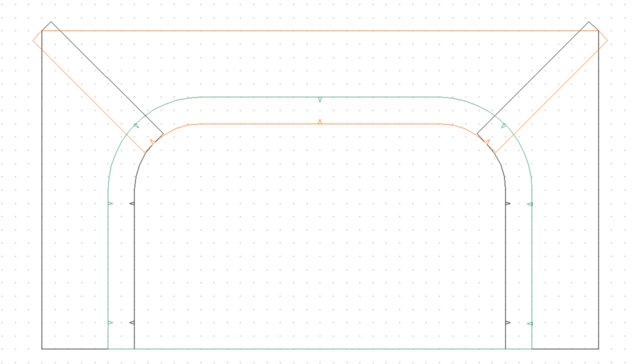

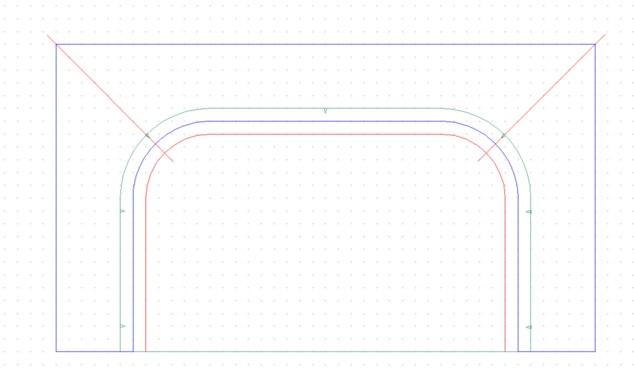

The red is the outer band and the green is the insert. With 1/2 seam allowance. So, there's 1" between the two:

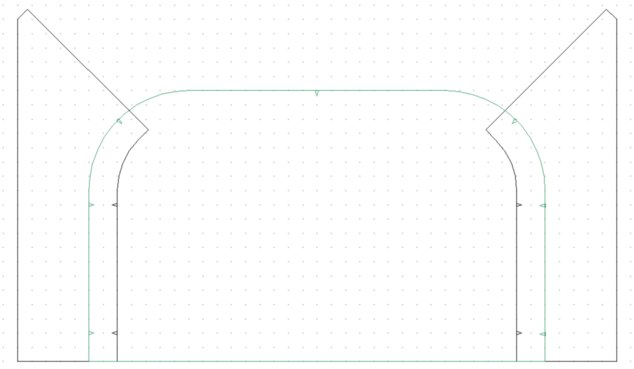

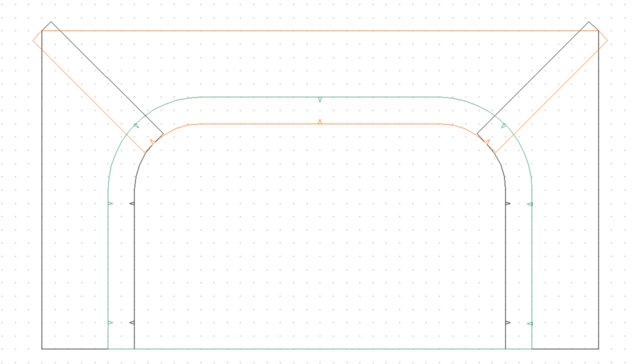

The final patterns with seam allowance for each part:

-

Amelia Brooker

5Thanks a lot Steven!! I really appreciate the pictures and the sample you made up, it really helps to clarify. I'll give this a shot tomorrow, makes a lot of sense, should solve my problem!

Amelia Brooker

5Thanks a lot Steven!! I really appreciate the pictures and the sample you made up, it really helps to clarify. I'll give this a shot tomorrow, makes a lot of sense, should solve my problem!

Welcome to The Hog Ring!

This forum is only for auto upholstery pros, apprentices and students. Join today to start chatting.

More Discussions

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring