-

Natalie Pankonin

6I'm mostly just griping here - I've used the cheap harbor freight glue guns - don't work. I used the EZE glue gun, doesn't work, I've used two different K-grip spray guns - they work just fine for lighter adhesives, but the second I put Weldwood in it, it clogs up. I am tired of wasting my time screwing around with the glue gun when I need one to work. Do I just have an evil glue gun gremlin or what? I read where all of you use the cheap harbor freight ones and they work just great for you. My space is limited so I need to stick to something in that size range - but sheesh - I'm ready to take the thing out to my gun range and use it for target practice! Any new suggestions? Thanks

Natalie Pankonin

6I'm mostly just griping here - I've used the cheap harbor freight glue guns - don't work. I used the EZE glue gun, doesn't work, I've used two different K-grip spray guns - they work just fine for lighter adhesives, but the second I put Weldwood in it, it clogs up. I am tired of wasting my time screwing around with the glue gun when I need one to work. Do I just have an evil glue gun gremlin or what? I read where all of you use the cheap harbor freight ones and they work just great for you. My space is limited so I need to stick to something in that size range - but sheesh - I'm ready to take the thing out to my gun range and use it for target practice! Any new suggestions? Thanks -

Fred Mattson

152Weldwood glue will usually spray from the standard cup gun.

Fred Mattson

152Weldwood glue will usually spray from the standard cup gun.

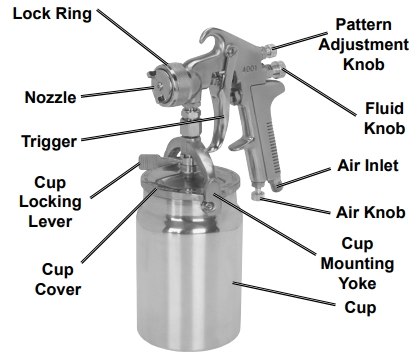

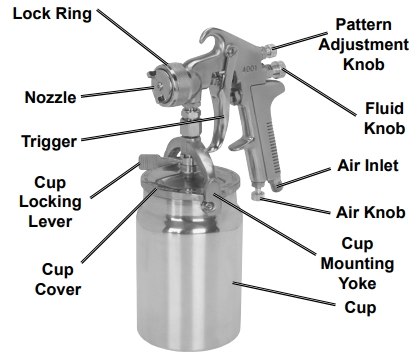

Things to check for:

1. Air Pressure should be about 80 to 90 PSI

2. The vent must be kept clear for the glue to be drawn through the gun properly

3. Over spray needs to be cleared from the air cap and nozzle to get an even spay pattern.

-

Natalie Pankonin

6My air pressure is set at 90, the vent is open, the cap and nozzle are clear. Still won't come out, occasionally I'll get a glop of glue, but thats it. I've adjusted it a million different ways to Sunday - still not working. The lighter du-grip glue comes out just fine. Not the weldwood.

Natalie Pankonin

6My air pressure is set at 90, the vent is open, the cap and nozzle are clear. Still won't come out, occasionally I'll get a glop of glue, but thats it. I've adjusted it a million different ways to Sunday - still not working. The lighter du-grip glue comes out just fine. Not the weldwood. -

Andy Laird

43How long is the weldwood sitting in your gun between uses? Also ow old is your glue?

Andy Laird

43How long is the weldwood sitting in your gun between uses? Also ow old is your glue?

I use my glue gun on a daily basis most of the time, on occasion maybe 3 days between uses. I generally don't have issues. If it has been sitting for much longer I will back pressure and either thin out the glue left in the gun or discard and start fresh. I also agitate my glue can every time I fill my gun just by swirling the can. Then by laying it on its side for a few days then standing up for a few days. This will keep the solvents mixed with the solids, otherwise the solids will settle to the bottom.

I have a feeling your glue is old and thick or just sitting too long in your gun without use. Or its possible that the air pressure you are sending the gun is 90lb but the air pressure knob on the gun itself (if you have one) is not opened far enough or is malfunctioning. I highly recommend a gun with the air knob on the gun itself this makes it super easy to adjust the air while your spraying.

To back pressure (force out any thickened glue from the pick up tube) take off the cup and the air tip. Then while holding the trigger, use a blow gun with the rubber tip and blow air through the fluid nozzle, . Be sure your pickup tube is over a garbage can because it can go everywhere. This will force out any thick globs.

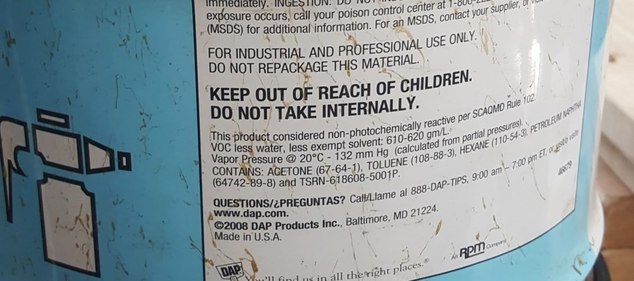

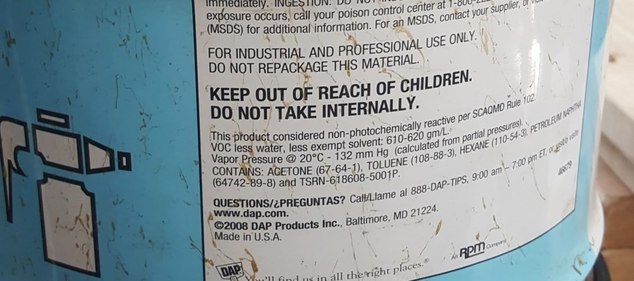

Then you can prop your gun upside down and pour in some acetone and let it sit for 10 min or so and back pressure again. Pour some acetone in a cup stick your guns pick up tube in it and spray straight acetone through it. This should have your gun cleaned out and ready to use again.

Or you may have gremlins??? Did you feed a mogwai after midnight, or get him wet?

The gun I use daily

-

Andy Laird

43Are you using the same gun for the du-grip and the weldwood? I would not mix these. Use different guns for each. Not absolutely sure but the mixing of the two may cause it to jell up causing clogs.

Andy Laird

43Are you using the same gun for the du-grip and the weldwood? I would not mix these. Use different guns for each. Not absolutely sure but the mixing of the two may cause it to jell up causing clogs.

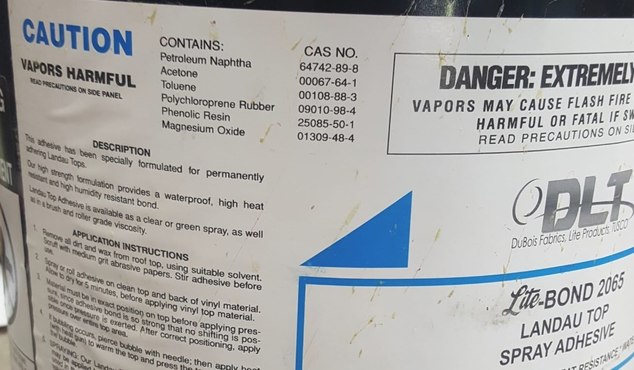

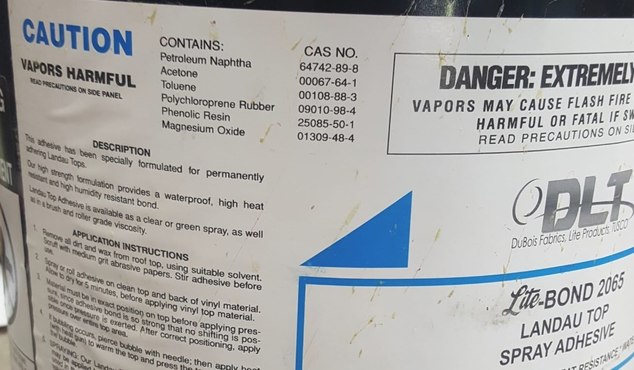

Just another quick note, I have been getting better results with the LiteBond from DLT over weldwood, And its less expensive -

Natalie Pankonin

6I buy the Weldwood by the gallon, I have had this particular gallon a month. If I do switch to du grip, I clean the gun first. I was having such issues with the gun today, that I cleaned it and tried the du-grip just to see if it worked. It did. Then I cleaned it again and switched back to the weldwood and again, it wouldn't work. The strange thing is I have been using this almost daily for the last several weeks and it's been functioning ok, I would have to stop and clean it every once in a while, but the last few days its just not working. And of course, I am on a deadline, trying to wrap some plastic trim for an airplane. I have the air pressure knob on my gun too and I have tried adjusting it to no avail.

Natalie Pankonin

6I buy the Weldwood by the gallon, I have had this particular gallon a month. If I do switch to du grip, I clean the gun first. I was having such issues with the gun today, that I cleaned it and tried the du-grip just to see if it worked. It did. Then I cleaned it again and switched back to the weldwood and again, it wouldn't work. The strange thing is I have been using this almost daily for the last several weeks and it's been functioning ok, I would have to stop and clean it every once in a while, but the last few days its just not working. And of course, I am on a deadline, trying to wrap some plastic trim for an airplane. I have the air pressure knob on my gun too and I have tried adjusting it to no avail.

I'm pretty sure I've got gremlins. I'm always up past midnight working in my shop - the little buggers must have snuck some of my sunflower seeds. -

Natalie Pankonin

6Does that gun work well with the weldwood? I may have to switch to DLT's litebond, I'm tired of wasting so much time with glue guns not working

Natalie Pankonin

6Does that gun work well with the weldwood? I may have to switch to DLT's litebond, I'm tired of wasting so much time with glue guns not working -

Joe Chiaramonte

12One thing to consider is nozzle size. I have seen the HF guns with various nozzle sizes. I routinely spray with an old Sharpe conventional spray gun I found at a yard sale. It was setup to spray primer using a 1.8 nozzle. I am able to spray with a good pattern as low as 60 psi. Never have an issue, never clean and use it at least every other day. I also have a pressure pot set up with a 2.0 nozzle by Binks years ago don't have issues with it either and don't use it nearly that much. Before I used the Sharpe I had purchased guns from Keyston Bros for around $35.00 they worked great had big nozzles and would still be using them today but they don't withstand dropping them that well. Was just at Home Depot and saw a gun with a 1.8 nozzle but have no experience with it. Not sure if this will help at all but just my 2 cents worth -

Hal Bast

13One thing you need to look at is air volume (cfm) even though you start with 90psi it will soon drop if you don't have the cfm to keep up. I ran into this wit a small air compressor. Sprayed good to start and then gobs. I had a small air compressor which worked good for a stapler, but not for a larger spray gun with glue. Just a thought

Hal Bast

13One thing you need to look at is air volume (cfm) even though you start with 90psi it will soon drop if you don't have the cfm to keep up. I ran into this wit a small air compressor. Sprayed good to start and then gobs. I had a small air compressor which worked good for a stapler, but not for a larger spray gun with glue. Just a thought -

Andy Laird

43I will interchange weldwood and the litebond without even cleaning the gun... Just not the du-grip with either the weldwood or litebond, the du grip is a completely different type of adhesive.. So I don't think the glue itself is your issue, but rather the consistency/viscosity of the glue.

Andy Laird

43I will interchange weldwood and the litebond without even cleaning the gun... Just not the du-grip with either the weldwood or litebond, the du grip is a completely different type of adhesive.. So I don't think the glue itself is your issue, but rather the consistency/viscosity of the glue.

The gallon can may cause an issue. Every time you open that can more and more solvent is evaporating through that large opening. You wont have this issue with the 5 gal bucket because the opening is only 2 inches or so. Maybe just puncture a few holes in the lid of the gallon can. Say 2 holes on one side to pour glue from, and 2 holes on the opposite side of the lid for vents. when you are done pouring just put masking tape over the holes. This way you wont have to open the can every time and avoid evaporation.

Nozzle size and cfm are also things to consider. I personally have never worried about either and spray just fine... I have a 60 gal 17cfm compressor now but for years just used a small 15 or 20 gal craftsman and never had a problem with it either.

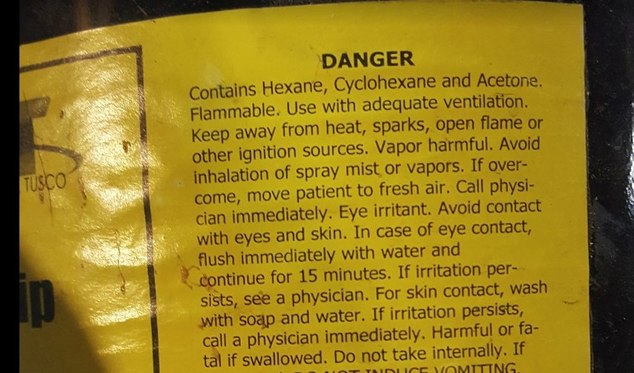

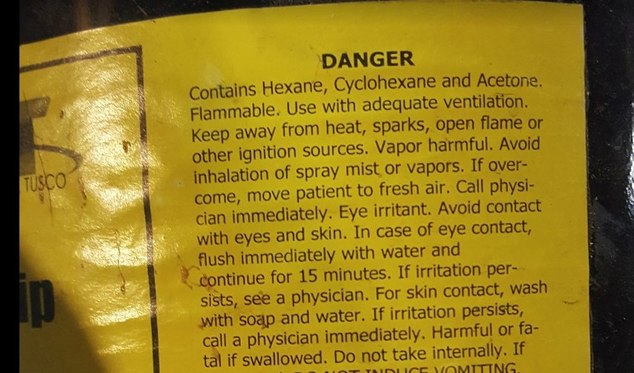

All said and done I think your main prob is the thickness/viscosity of the glue. I would try thinning your glue Litebond or Weldwood, not the du-grip with acetone and see how that works. when in doubt about thinning glue look on the can for contents. Use a solvent that the glue contains from the factory

-

Natalie Pankonin

6Thank you. I kept thinking that it couldn't be the glue since the can was so new and I've almost gone through the whole can, but the further I progressed, the more issues I had with it. I did take the air inlet plug off my gun just to double check that - even though no glue ever goes through there - I just wanted to be sure everything was good. That part of the gun is made of pot metal and a little chunk fell out and lodged in my finger. So even though I have never dropped the thing, somehow that little piece cracked off and that has to be the bulk of my issue. I am going to order this gun https://www.yourautotrim.com/aespradspgun.html - I just don't have good luck with anything HF and I would rather spend a little extra then have to buy something multiple times. Even though this makes the 5th glue gun I've bought in two years!

Natalie Pankonin

6Thank you. I kept thinking that it couldn't be the glue since the can was so new and I've almost gone through the whole can, but the further I progressed, the more issues I had with it. I did take the air inlet plug off my gun just to double check that - even though no glue ever goes through there - I just wanted to be sure everything was good. That part of the gun is made of pot metal and a little chunk fell out and lodged in my finger. So even though I have never dropped the thing, somehow that little piece cracked off and that has to be the bulk of my issue. I am going to order this gun https://www.yourautotrim.com/aespradspgun.html - I just don't have good luck with anything HF and I would rather spend a little extra then have to buy something multiple times. Even though this makes the 5th glue gun I've bought in two years!

I never mix du grip and contact cement. They are two very different glues. Thanks for all the suggestions everyone. Hopefully a new gun solves my problems. Very frustrating as I've wasted more time trying to get the thing to work than I want to admit to -

Natalie Pankonin

6Got the new glue gun today - Merit pro - it works awesome! I was getting really frustrated with that other gun, kept thinking it was the weather since it was a little cool. This one makes it effortless. Thanks everyone for all your suggestions.

Natalie Pankonin

6Got the new glue gun today - Merit pro - it works awesome! I was getting really frustrated with that other gun, kept thinking it was the weather since it was a little cool. This one makes it effortless. Thanks everyone for all your suggestions. -

Fred Mattson

152Thank you for posting your results. Not everyone follows through when the begin a post and it leaves us all wondering what the solution was.

Fred Mattson

152Thank you for posting your results. Not everyone follows through when the begin a post and it leaves us all wondering what the solution was.

Again, Thank you.

Welcome to The Hog Ring!

This forum is only for auto upholstery pros, apprentices and students. Join today to start chatting.

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring