-

Seat ConstructionYou may want to cut out openings on the driver and passenger side of the board. Staple some elastic webbing to provide a little bounce to the cushion. I like to use marine ply for the strength.

-

LeBaron BonneyVery sad to hear. They were one of the few remaining suppliers to offer our industry original replacement wool fabrics for antique cars.

-

Thread issue on new thread...I discovered that also. Thread does have a shelf life. If you have boxed pre wound bobbins check them as well.

-

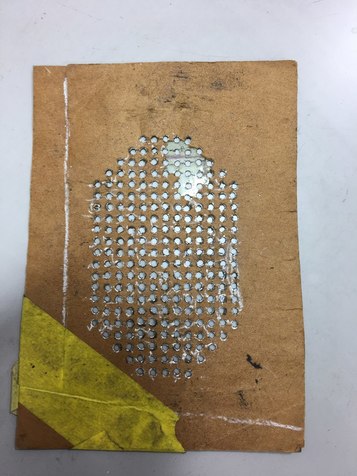

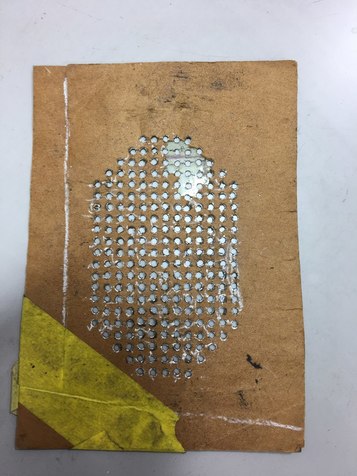

Perforating VinylHal. These are some of my templates I’ve used. Try printing them and glue onto a piece of vinyl or clear plastic. Hope this will help.

-

50s cadillac trim specialist ??Yes, I agree with you Fred. Intense labor. Very detailed with many pieces. Try contacting Jenkins Interiors in North Carolina. I recently installed a set they fabricated for one of my customers. Decent fit and properly made.

-

Horizontal PleatsIt may be just aesthetics. A bench seat using only vertical pleats looks better than horizontal pleats without being broken up with any solid vinyl. It may also be an impression left from the seat cover days of the past ,that would use press roll and pleat vinyl which the width is only 54" not enough to be used horizontally.

-

NOS VinylThat NOS vinyl can be really stiff and difficult to work with. If you have access to a steamer, that would help .Steaming the back of the vinyl slowly will soften that canvas backing.

-

Perforating VinylYes, This can be a tedious process! This is what we've always done. We create a template out of clear rear plastic window curtain with all the holes correctly marked and punched thru. Cut a piece of black waterproof panel board to the same design and size ,then split in half. Glue your finish vinyl onto the split black water proof panel board. ( The split board gives strength to the vinyl but still allows to punch thru easily) Mist glue on only the template plastic, place on top of the vinyl/panel board piece. ( The misted glue allows the template to lightly stick in place) Then mark all the holes with a china marker. Lay onto a flat cutting board and punch away.

-

Convertible topsI'd be happy to give you any advice on line or via phone whether on general installation or specifics.

-

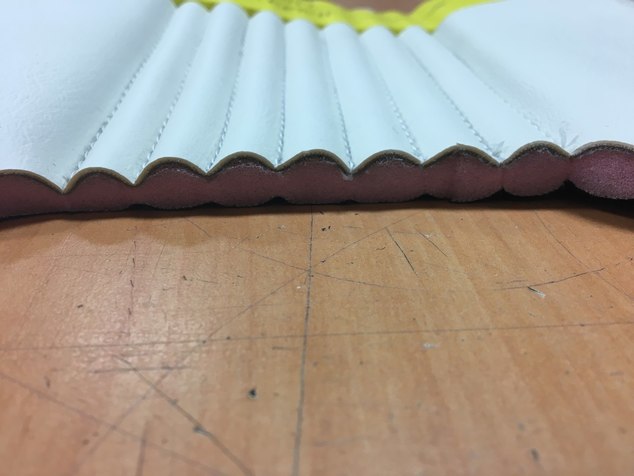

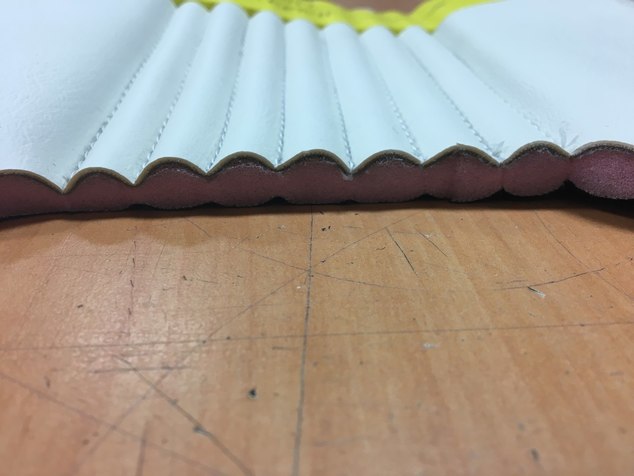

Pleats

I've used this method which seems to work well on very narrow pleats. Glue 1/2" pad onto bowlining which strengthens the padding and will stop it from stretching. Mark your lines on the vinyl to 5/8" for 1/2" finish allowing the stretch of vinyl to go side to side on the pleat. This allows the narrow pleat vinyl to stretch over the foam when sewn. Glue the vinyl onto 1/8" pad. Lay on top of foam (no glue) and sew. -

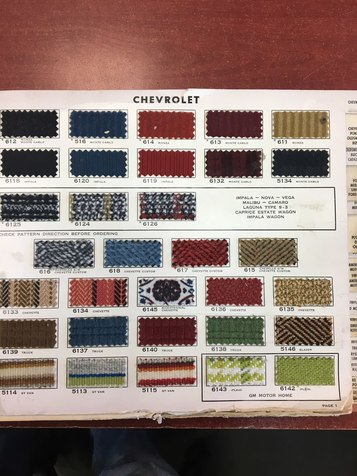

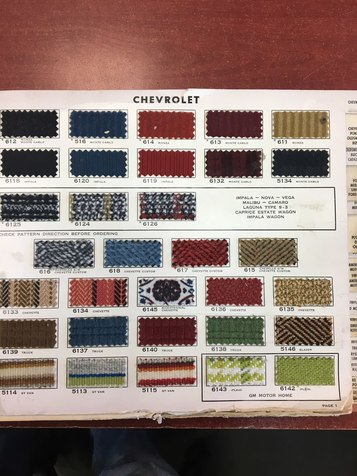

76 Impala Red

SMS is the only source that I know of that is actively obtaining and preserving older body cloth. He purchased a full trailer load of my older stock . I find pictures with a Deleo/Detroit Number works best. This is from the 76 Deleo book. I hope this helps. -

Button machines for leather/ thick fabricCheck out C.S. Osborne NO.W-1 Hand press machine. Works great for buttons and grommets.

-

stuffed cotton pleates.I pre make the cotton inserts to the desired size and wrap them with a thin (1/16") headliner smooth side out. Slide them into the pleat channel with a ruler or cut to size waterproof panel. Pre making helps to keep the cotton consistent and eliminates bunching.

-

Shaping/bending Pin BeadingThat'll be perfect. Try making the bend in the middle of the bead length. You can then join together on the straight by placing a solid piece embedded into the lead. If there is a ripple or wave in the bead It can always be sanded then covered.

-

Shaping/bending Pin BeadingHi Joseph, Is this beading to be covered in leather , painted or chromed when complete. On tough curves, we've taken the lead out and shaped just the brass.

-

Shaping/bending Pin Beading

Make a bending board to the desired curve. Insert the bead, heat it and slowly bend it to shape. -

Panel Board Shelf above Upholstery Table

I built two shelves on an angle under one of my tables which accommodates both sizes perfectly. Easy to drop in the panels as well as removing with the aid of a flat plier. After years of various storage methods, this seems to work the best. -

Split benchIf the customer is not a purest, another option would be burlap, jute , one inch foam, with a dacron top layer. We use this method with great results.

-

stuffed cotton pleates.I agree with you. I've always made the base taunt and the top cloth material fuller.This allows the fullness of the pleat to be seen on the top side.

-

Wrinkling -internal bendsTry steaming from the underside. I find it's best on curved areas like this to cut the vinyl on the bias which would allow it to stretch in all directions. You may want to cut it slightly tighter so the material can be pulled to fit.

-

Sunroof issues.Try Bayside Auto Trim, Wall NJ . (609) 226-8385 . Speak to George, he gets into older car sunroof repairs. He may know a source.

-

Nylon versus Polyester ThreadHi Matt, I've doubled up thread to make it thicker and sewn with it. Give it a try.

Eric Gordon

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring