-

Scanning patternsPosted these photos in another thread as well.. Sample panel to get the idea across.

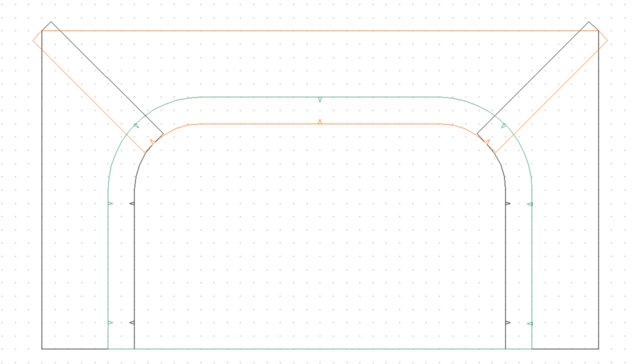

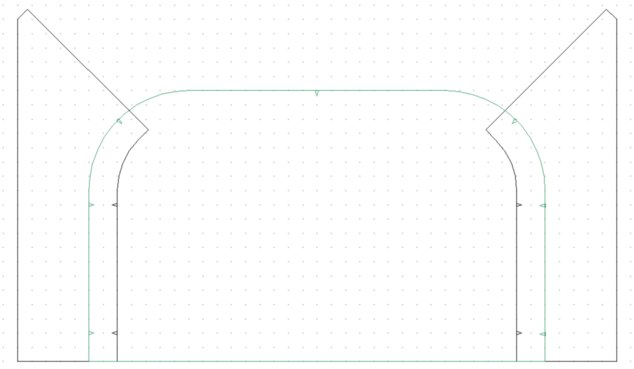

Seams:

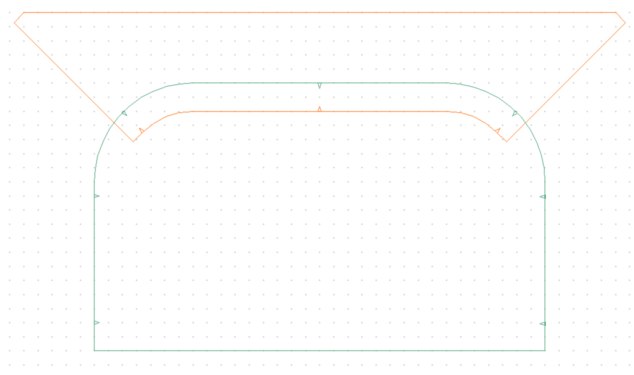

All of the parts:

With seam allowance:

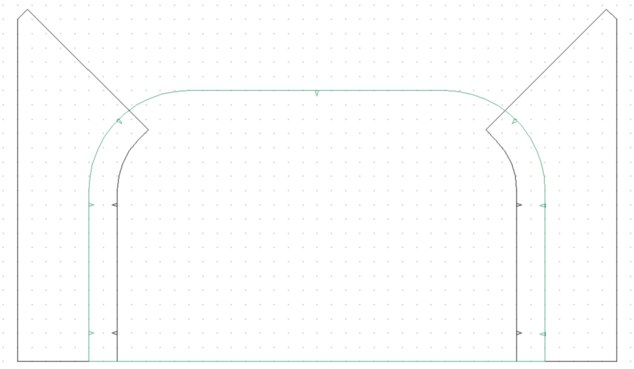

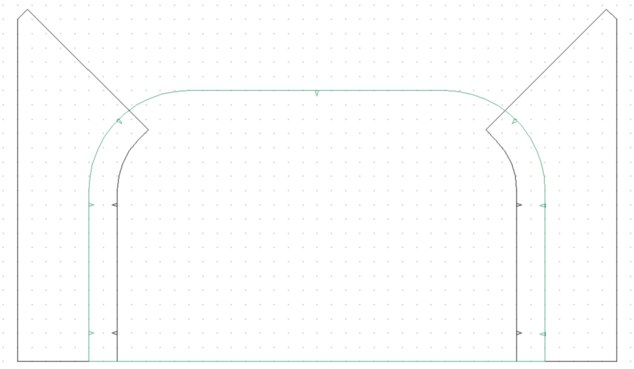

Split out to show the three pattern pieces:

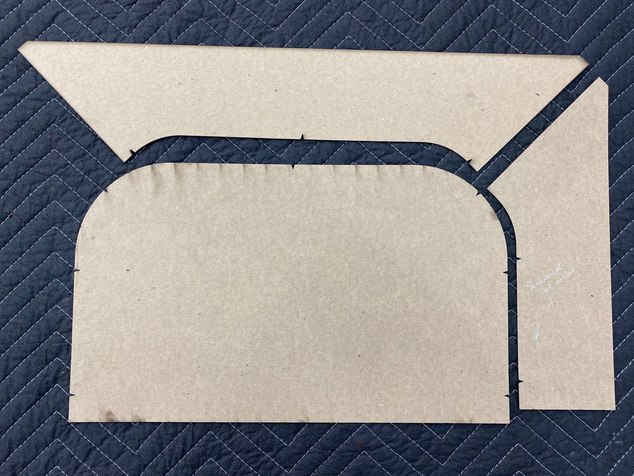

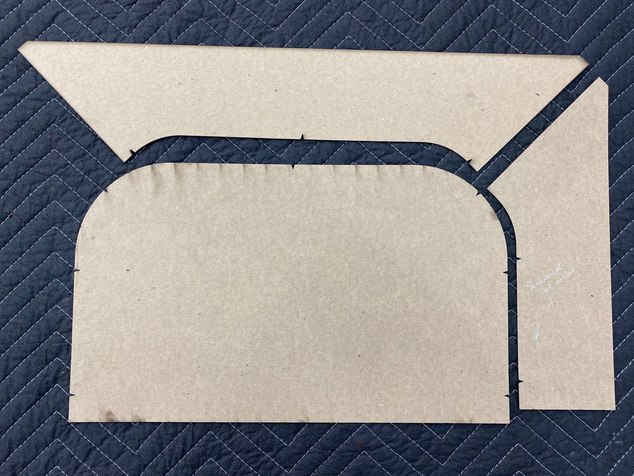

Patterns cut out of chipboard on the laser:

Finished part:

-

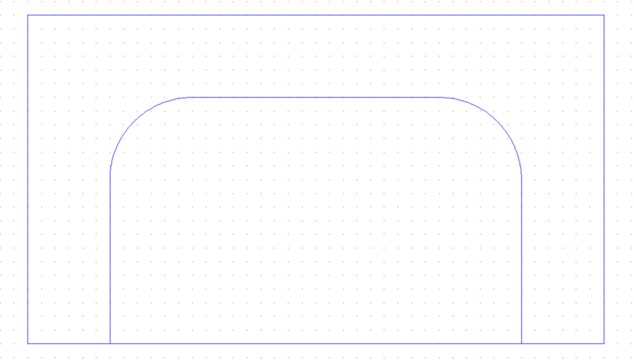

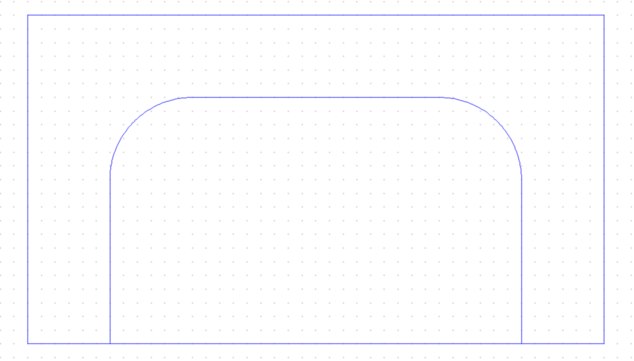

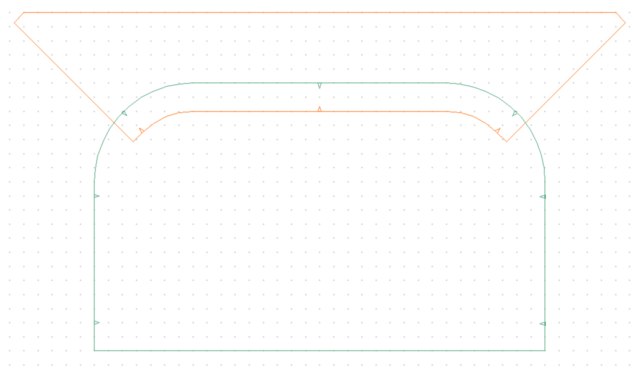

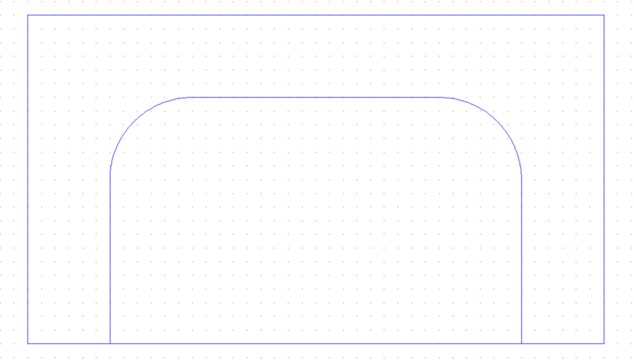

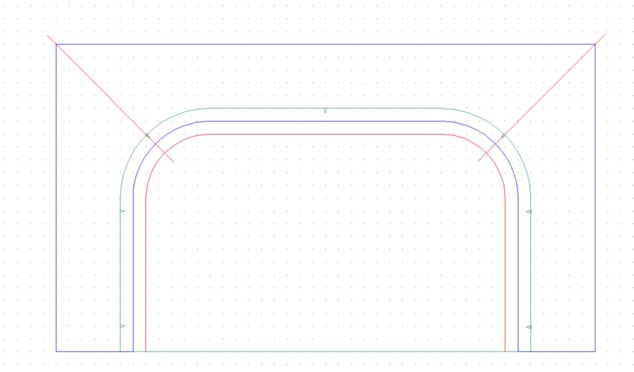

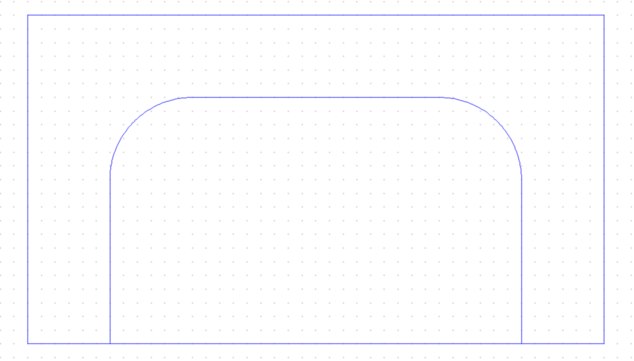

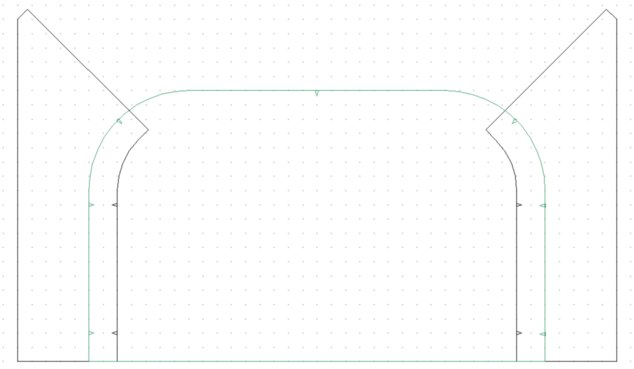

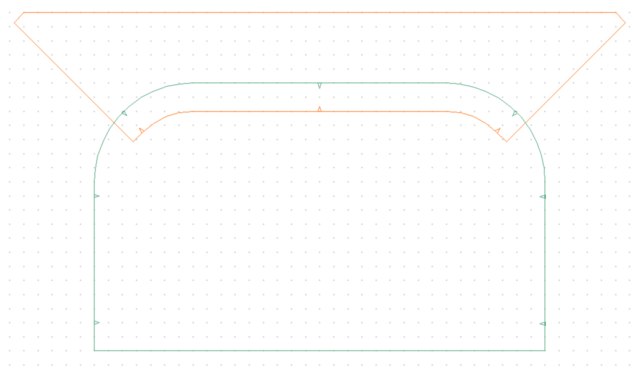

Sewing Rounded InsertsFor stuff like this, I find it much faster to draw it in CAD and cut chipboard patterns on the laser. For this example the blue is the seam:

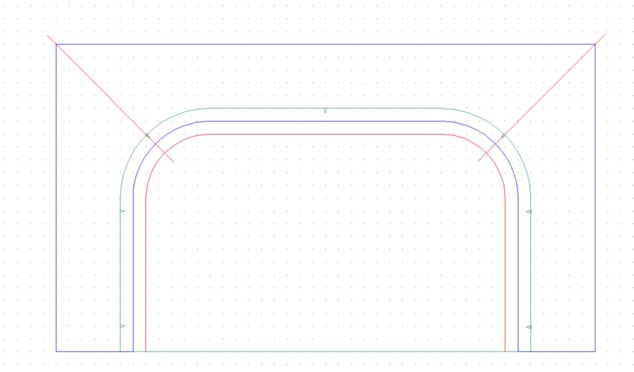

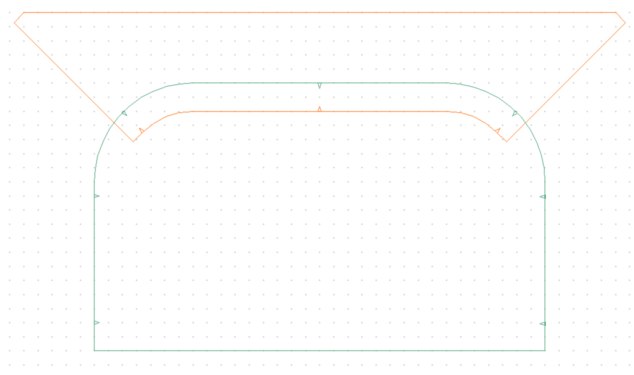

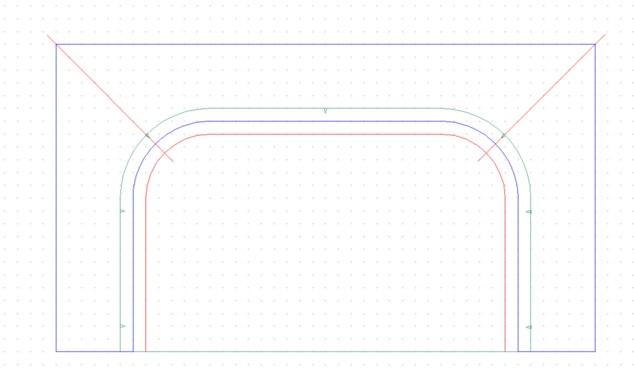

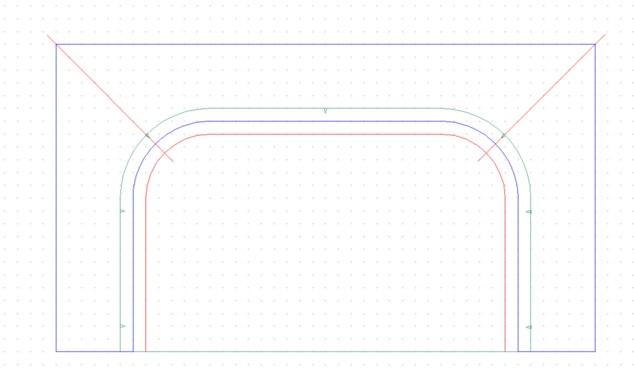

The red is the outer band and the green is the insert. With 1/2 seam allowance. So, there's 1" between the two:

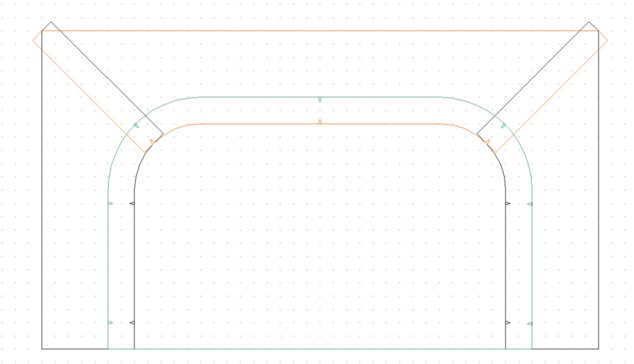

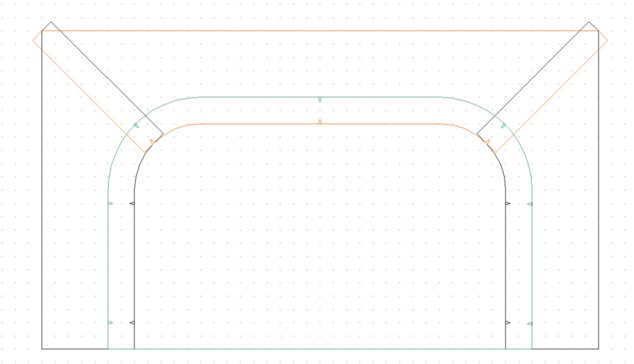

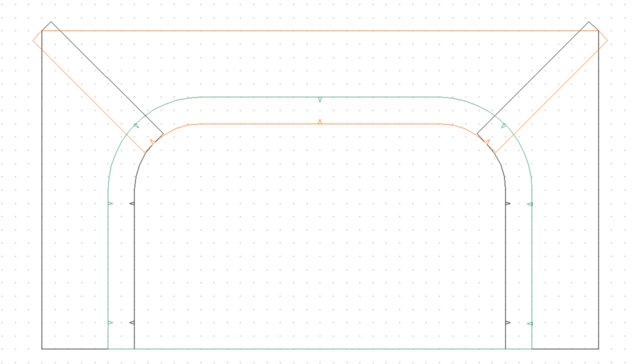

The final patterns with seam allowance for each part:

-

CNC Sewing Setups: Brands/Prices/Reviews/Pros-Cons?Richpiece will get you a quote quick. If I remember correctly, the machine I looked at was around $40k.

-

Scanning patternsI draw seat inserts and such in CAD and make a chipboard template for each part on the laser. It's much faster than drawing by hand. Really works well for flat sections. The rest, I do the old fashioned way to make the pattern. If I'm doing a lot of the same seat, I'll digitize the pattern and cut chipboard templates on the laser. It's a great way to work.

-

Sewing Rounded InsertsThe trick I've learned is you need to offset the outside band's radius by your seam allowance. I'll use 1/2" to make it easy. So you have a 3" radius seam. The insert will be 1/2" larger. The band will also 1/2" larger. This means there's 1" total overlap (2 times the seam allowance) between the two pieces. I find it works well to use staples to hold everything together while you sew it, if you are having problems with it all lining up.

-

600 Watts 110 Volt Servo Motor for Industrial Sewing MachinesI've always been happy with Gregg at Keystone Sewing in Philly.

-

glue pressure potI have the same gun as Joe. I bought it from Perfect Fit-McDonald. They sell the gun setup for adhesive. I also only spray weldwood. I bought the pot used. Rebuild kits for the old regulators were easy to find online for a couple bucks.

-

Thoughts about double needle sewing machinesI have a Seiko split needle bar post bed machine. Well worth the expense.

I also have Consew 339RB in 1/4 and 3/8 gauge. Again, very happy to have them in the shop. -

Juki 1508NH Sewing MachineIf it's in the budget, I highly recommend either a Durkopp M-Type or for a LOT less, the Juki LU-2810A-7. It has a high step mode that is selectable at the push of a button to high-step the foot, along with auto back tack and thread trimmer. Well worth the expense. It will dramatically improve your output.

Steven M

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring