-

Cody Lunning

39Not sure how effective this would be from day to day use, but wondering if anyone else had used this to make their patterns?

Cody Lunning

39Not sure how effective this would be from day to day use, but wondering if anyone else had used this to make their patterns?

https://m.youtube.com/watch?v=lJV9IUJHRtk&feature=youtu.be -

Jesse Durkee

19I would like to find a way to use a digital pattern but I have not figured how it would save time or money for a small shop. I get it if you are pumping out lots of cutting where you and have an employee just cutting the same pattern vs a cnc cutter.

There’s also autometrix’s cadshot where you just use an android phone or tablet to take a pic and it does the rest. -

Cody Lunning

39Yeah this would be handy if you did production runs, and I have thought about it for some seats. You’d almost have to have a scanner of some sort, but I think it could save some time once you get use to running the program

Cody Lunning

39Yeah this would be handy if you did production runs, and I have thought about it for some seats. You’d almost have to have a scanner of some sort, but I think it could save some time once you get use to running the program -

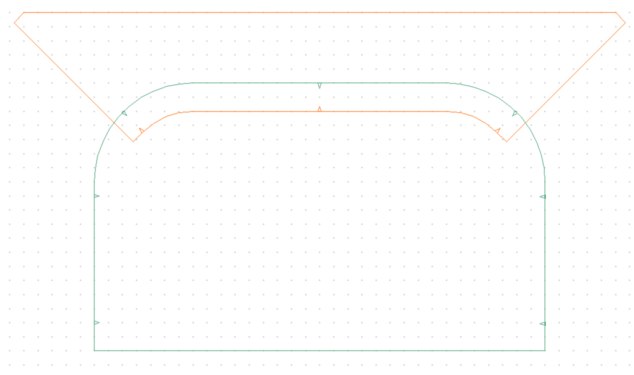

Steven M

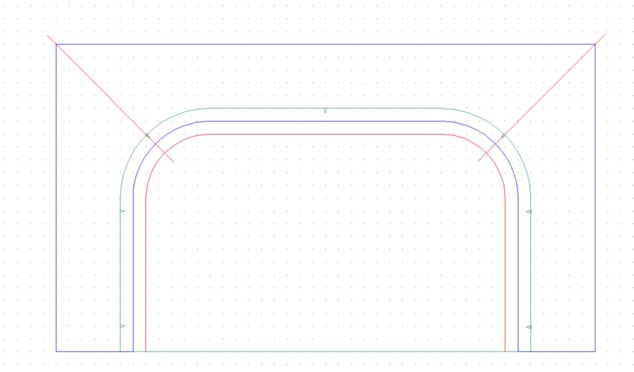

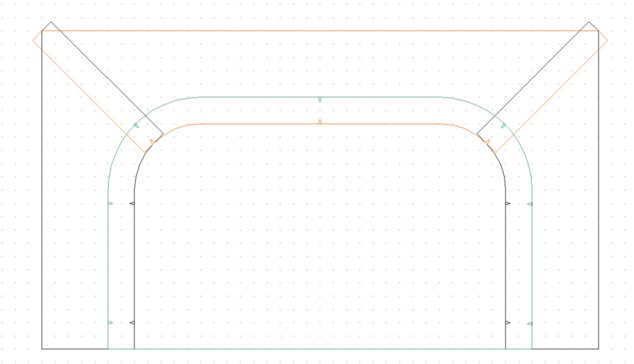

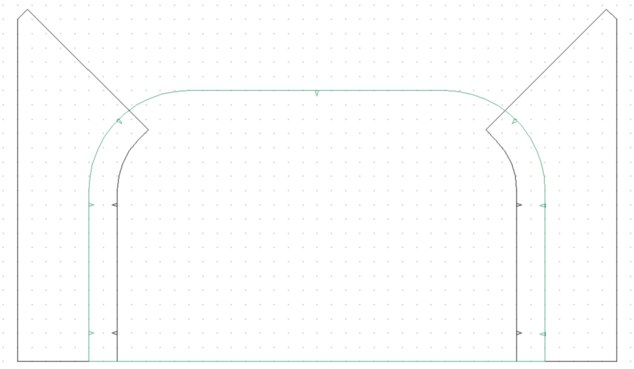

3I draw seat inserts and such in CAD and make a chipboard template for each part on the laser. It's much faster than drawing by hand. Really works well for flat sections. The rest, I do the old fashioned way to make the pattern. If I'm doing a lot of the same seat, I'll digitize the pattern and cut chipboard templates on the laser. It's a great way to work. -

Cody Lunning

39@Steven M I use to have solidworks but no longer do. But I have been making some chipboard patterns by hand for audi seats. Holding theyll come in handy.

Cody Lunning

39@Steven M I use to have solidworks but no longer do. But I have been making some chipboard patterns by hand for audi seats. Holding theyll come in handy. -

Bill holloway

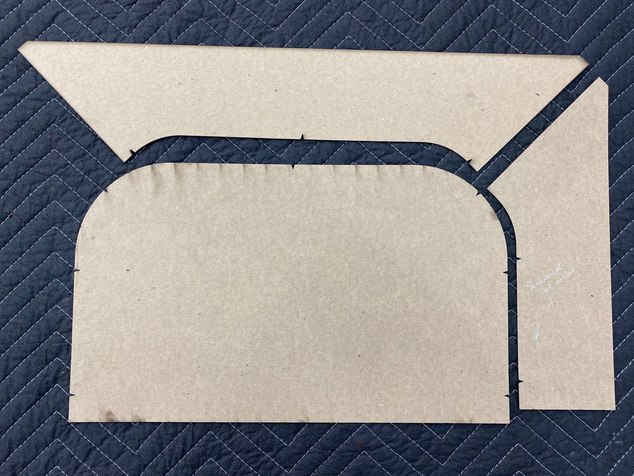

2the laseris a great tool I use mine for tons of fab patterns on consoles and door panels . Usually use abs and use it to rout out parts. Also I cut my material on repeat bomber seats. Even engrave patterns on the material.Attachments

Bill holloway

2the laseris a great tool I use mine for tons of fab patterns on consoles and door panels . Usually use abs and use it to rout out parts. Also I cut my material on repeat bomber seats. Even engrave patterns on the material.Attachments IMG_0690

(244K)

IMG_0690

(244K)

IMG_0727

(328K)

IMG_0727

(328K)

IMG_1910

(185K)

IMG_1910

(185K)

Welcome to The Hog Ring!

This forum is only for auto upholstery pros, apprentices and students. Join today to start chatting.

More Discussions

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring