-

Automotive Upholestry ThreadsThe OTC nylon contrast thread works well. Just do not use it on motorcycle, boat, or even convertible seats. It fades real fast. For a better color selection in the smaller/ normal size thread you would tend to look at the Sunguard poly which will also fade. I have had so many issues with the Sunguard poly leaching color and staining clothing, I will be switching to Amann thread.

I have heard many good things about Amann right here on THR. Most of that discussion was on the old forum and is no longer accessible.

Maybe others can expand on Amann's quality and color selection -

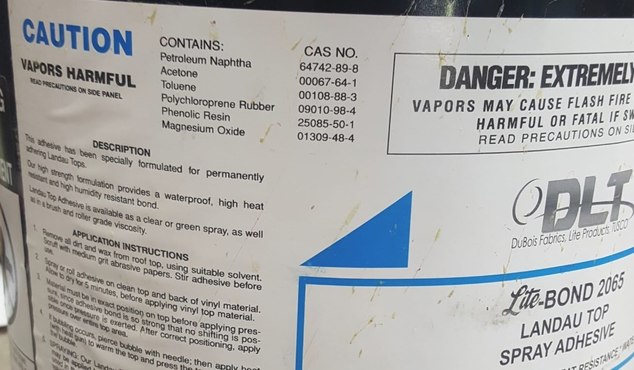

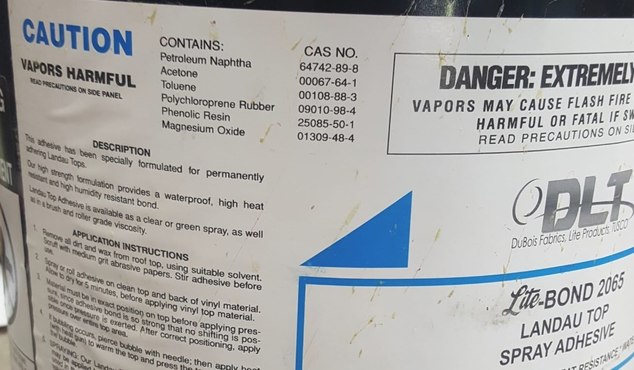

Material supplierMy main suppliers for foam, vinyl, and supplies are DLT and Midwest Fabrics. I do order from Keyston Bros and Miami on occasion. Because Im close to both Midwest Fabrics and DLT I like to order glue and oversize stuff from them and have delivered on their sales runs. Avoiding the hazardous ship charge on 5 gal glue is a nice benefit

Acme for headliners, Electron for tops, Hhydes for leather, GAHH for carpeting and European specific materials. I used to buy pre-formed from ACC but I can buy their stuff online for less than buying straight from them with my discount.

In general I try to order from suppliers that are close for better shipping prices via speedy delivery(in the Midwest only) its 1/2 the cost of shipping vs ups or fedex . I also consider weather my supplier sells to the general public. I expect to be able to mark up material prices. Kind of hard to do that if the customer can buy for the same price that I can. Though that is getting harder and harder to do in the on-line age. -

Glue gun issuesI will interchange weldwood and the litebond without even cleaning the gun... Just not the du-grip with either the weldwood or litebond, the du grip is a completely different type of adhesive.. So I don't think the glue itself is your issue, but rather the consistency/viscosity of the glue.

The gallon can may cause an issue. Every time you open that can more and more solvent is evaporating through that large opening. You wont have this issue with the 5 gal bucket because the opening is only 2 inches or so. Maybe just puncture a few holes in the lid of the gallon can. Say 2 holes on one side to pour glue from, and 2 holes on the opposite side of the lid for vents. when you are done pouring just put masking tape over the holes. This way you wont have to open the can every time and avoid evaporation.

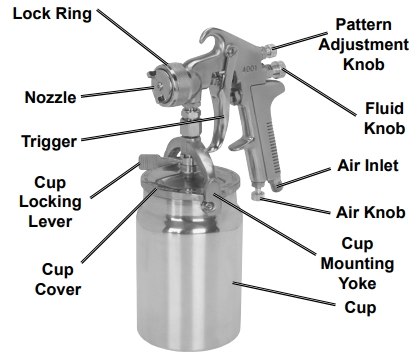

Nozzle size and cfm are also things to consider. I personally have never worried about either and spray just fine... I have a 60 gal 17cfm compressor now but for years just used a small 15 or 20 gal craftsman and never had a problem with it either.

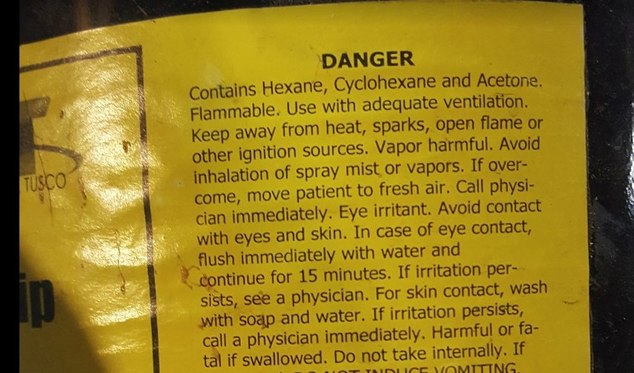

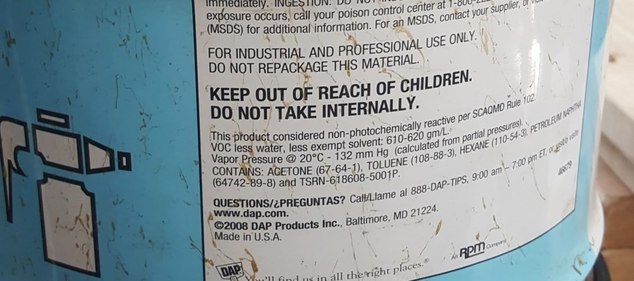

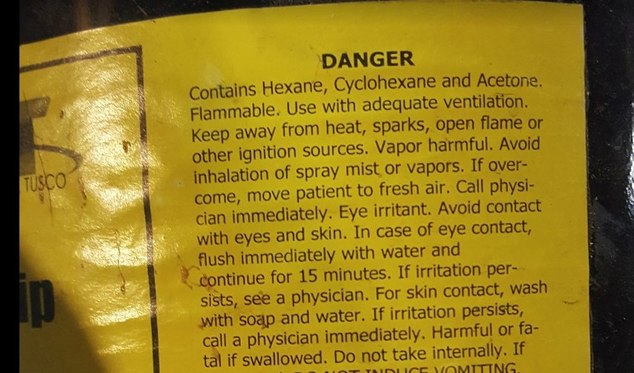

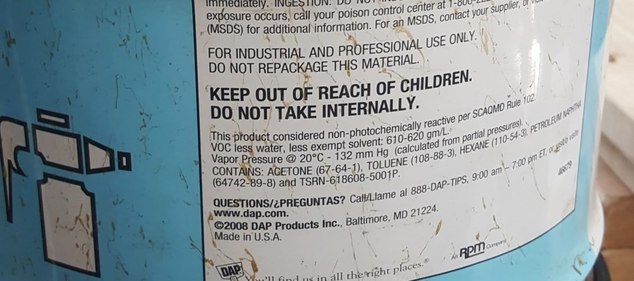

All said and done I think your main prob is the thickness/viscosity of the glue. I would try thinning your glue Litebond or Weldwood, not the du-grip with acetone and see how that works. when in doubt about thinning glue look on the can for contents. Use a solvent that the glue contains from the factory

-

Glue gun issuesAre you using the same gun for the du-grip and the weldwood? I would not mix these. Use different guns for each. Not absolutely sure but the mixing of the two may cause it to jell up causing clogs.

Just another quick note, I have been getting better results with the LiteBond from DLT over weldwood, And its less expensive -

Glue gun issuesHow long is the weldwood sitting in your gun between uses? Also ow old is your glue?

I use my glue gun on a daily basis most of the time, on occasion maybe 3 days between uses. I generally don't have issues. If it has been sitting for much longer I will back pressure and either thin out the glue left in the gun or discard and start fresh. I also agitate my glue can every time I fill my gun just by swirling the can. Then by laying it on its side for a few days then standing up for a few days. This will keep the solvents mixed with the solids, otherwise the solids will settle to the bottom.

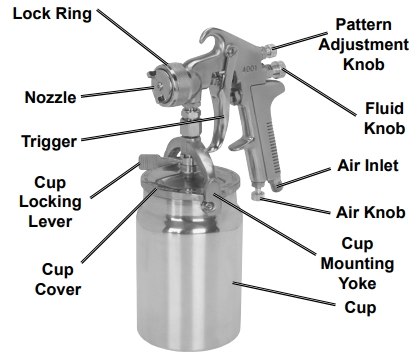

I have a feeling your glue is old and thick or just sitting too long in your gun without use. Or its possible that the air pressure you are sending the gun is 90lb but the air pressure knob on the gun itself (if you have one) is not opened far enough or is malfunctioning. I highly recommend a gun with the air knob on the gun itself this makes it super easy to adjust the air while your spraying.

To back pressure (force out any thickened glue from the pick up tube) take off the cup and the air tip. Then while holding the trigger, use a blow gun with the rubber tip and blow air through the fluid nozzle, . Be sure your pickup tube is over a garbage can because it can go everywhere. This will force out any thick globs.

Then you can prop your gun upside down and pour in some acetone and let it sit for 10 min or so and back pressure again. Pour some acetone in a cup stick your guns pick up tube in it and spray straight acetone through it. This should have your gun cleaned out and ready to use again.

Or you may have gremlins??? Did you feed a mogwai after midnight, or get him wet?

The gun I use daily

-

Sew foam questions for all the trimmersDidn't think to mention this earlier. For those that have trouble when perimeter sewing long or awkward parts. Use your stapler's pin side to hold everything in place, then just pull the pins as your sewing.

-

Alternatives to AlcantaraHydes is the exclusive dealer of Alcantara in the US from my understanding.

-

Best machine for the best price to sharpen scissors recommendations please

Ive used several diff machines for sharpening. Even the fancy grinder with the articulating arm to hold at the proper angle. Which is pretty $$. But the best sharpening tool i have ever used is this one, $7.00 to $11.00 at the hardwhere store. Does knives also. Though the knife part is not so great.Attachment 20180321_100146

(110K)

20180321_100146

(110K)

-

Glue potI have used that style glue pot before. They work pretty good. The problem is that the glue will dry out fairly quick, and they are hard to clean. I don't brush glue on very often, maybe once every other week so they don't make sense for me. I normally just use an old glass pickle jar, when the glue hardens in the jar I just pitch it and grab a new one.

-

Custom foam seat (listing)I normally use a Dremel, or oscillating tool to cut the channels. The multi tool/oscillating tool works well for cutting the edges also instead of using a standard blade to cut out the sides. For the multi tool I just use a scraper blade and sharpen it almost to a razor edge.

-

Best door panel substrateYes heat then vacuum. I just built a vacuum box out of wood and used pegboard for the top then a shop vac inside with the switch wired through the box, along with exhaust port. The vac could easily be outside, also wouldn't need to wire in a separate switch. Eventually I plan on building a heat box/oven to be able to control temp of the ABS, but for now I just use my acetylene torch, or a big propane weed burning torch to heat the ABS. Its real hard to control the heat that way though.

And yes a wood sample to form over, or carve styrofoam wrap it with plastic wrap and a layer of fiberglass over that. At that point you could just make it with the fiberglass but that is a lot of mess and expense in matting and resin. In either case the heat of the thermoforming or resin chemicals will melt the styrofoam. Wood is a better model but foam is much easier to carve. -

Custom foam seat (listing)Miami has the hard hook. I have not noticed it at any of my other suppliers. I have used dual lock before for the same purpose with good results. Of course using the soft seat velcro on the cover. I think DLT also has the soft velcro backed 1/2" sew foam, though its not listed on the website, I'm sure I saw it in one of their flyers.

Here is a quick sample of 2 ways to use Velcro listing. On the left using standard non sticky back hook glued into place. On the right using hard hook glued into a channel.

-

Separating cloth from foamwhat about an oscillating tool with a scraper blade. I use them a lot for scraping material off of panels, channeling foam with a sharpened scraper blade, or just cutting a multitude of things. I've never tried it to remove cloth from foam with it, but it's worth a try. It's a very handy tool to have around.

-

Trim fixing /panel clipsMany of the clips mentioned above work well but the problem is the fiberglass that they will attach to. If the fiberglass is too thick the clip won't expand on the back side of the hole. If the fiberglass is too thin the clip will expand but may tear out the fiberglass when removing the panel.

This may be another option, once again I have not tried this with fiberglass doors but may be worth a try. install these sockets first with some epoxy, then use the AU12134 clip. The nice thing with these clips is that they lay flat on the panel. Which means less chance of a lump (or foaming and sanding) on the covered side of the panel unlike wire or plastic clips. If you try it and the sockets do not work I believe the hole made for the socket will still accept a Christmas tree style clip. -

Small shop layout ideasYeah that would make a difference. I have space for 1 car at a time. Though it would be nice to have room for a boat or limo, or that Humvee I did next to my garage last summer. If your a one man shop, 2 stalls is really all you need, 1 stall for the car and 1 for work space. More space is always desirable but small areas can make good work shops.

-

Top stitching feet?

I see your machine is a Mitsubishi. does it use consew style feet or are they both round attachments? If so have you found a place that has feet for a reasonable price? here is what my feet look likeAndrew Bodnar —

-

Auto CarpetThat's a good tip Geoff

The problem with the Eastwood was not the adherence to the cabinet but the butyl itself melting. It stuck to my cabinet just fine, then melted and slid down 4-5" till it just fell on the floor, leaving a gooey mess behind. can you imagine that dripping through the drain holes in the door of a $$ car? It may have been a one off problem, but I'm not willing to trust a customers car to a product I have witnessed failing. -

Trim fixing /panel clipsFiberglass cars can be tricky due to the uneven thickness of the fiberglass itself. On steel cars I use Auveco AU12134, but these do not work well with glass cars.

- I do not like the christmas tree clips but they are probably the most readily available solution.

-There are some nice looking clip systems called Fastmount I have not used them yet but I do plan on it the next time a glass car comes in my shop.

- You could also use Dual Lock from 3M. it is basically a stiff plastic Velcro. I don't really trust the adhesive back, so I use rivets or staples to ensure the adhesive and/or paint wont fail. Standard velcro sticks to the Dual Lock as well, more so to the SJ3870 than the SJ3871 but it works with both. -

Trim fixing /panel clipsFiberglass can be tricky, due to the uneven thickness of the fiberglass. On steel cars I use Auveco clip AU12134. I used snaps on one glass car, it worked pretty well but I prob. would not do that again. I'm not a fan of the Christmas tree clips but that may be the best readily available option.

-There are some nice looking clips called Fastmount I have never used them but plan on it the next time I work on a glass car.

-You could also use the 3M Dual Lock which is basically a plastic Velcro This works pretty well, I just don't always trust the adhesive on this stuff. I normally use rivets or staples along with the adhesive back. Soft Velcro works well with the Dual Lock as well -

Auto CarpetHere is a pic of Eastwood butyl vibration damper that i mentioned earlier. Out of multiple brands only the Eastwood brand melted.

-

Best door panel substrateI use ABS for every panel I have built in the last 15 years. I'm in Illinois so we get hot and humid in the summer and below 0 in winter. I have not had any problems with ABS. Now I cant say how it would perform in hot dry climate like Arizona.

Direct heat will make ABS expand and uncovered ABS in the sun will swell. I would suggest at least 1/8" closed cell on top before you cover. I do think that a package tray warped with thin black vinyl would swell in the sun. I have never had a problem with it just adding the 1/8" closed cell.

The versatility of the ABS is hard to beat. It is also very easy to work with. Score and snap or use hand or electric tin snips to cut. I'ts easy to drill, will hold staples well, heat and shape (thermoforming). If you bend to far like 45° without heat it will snap. So just use a propane torch to slightly heat up the bend area. Around here a 4X8 sheet of .090 is about $35. If you mess around with it enough you can make some pretty cool stuff

-

Lighting!Wow that's a big space. I Just changed my shop to led tubes and I absolutely love them, but I'm in a 22 x 24 garage.

This is what I used for my lights. Maybe they would work for your main work and office area. Customers always want to look at samples in natural light, and I have to say that these are fairly close. Although nothing can replace natural light. Maybe you could add some sky lights and a few more windows to let in the natural light. LED's are very cost effective, but sunlight is free.

Andy Laird

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring