Comments

-

Head Rest PostI’ve done quite a variety of seats, and unless those things absolutely need to come out, id advise leaving them, fitting your cover, and then cutting them out last. You got the cover off without removing them, and working around it is always better than breaking them.

-

Thread size?I was going to say the same thing cody, i went years using all the other brands, moved over to E3 in south florida a year and a half ago. They introduced me to Serafil thread and oh man. what a game changer. Maybe not so much for UV thread, they do have a version of this for custom tops and such, which i just started dabbling with, but ill take their color fastness and choices over anything else ive used before. Thier 15 thread is definitely thicker, and closer to the 92 we are all familiar with. Thats what we use as our standard size, works awesome for top stitching and for general purposes. Sews well in my consew 206, bobbins run out quick, but its worth it. I switch up to the 10 for steering wheels to get it even fatter. Their 30 is close to the standard 69 but a little less available color wise.

-

Skiving seams.I'm curious with this myself. Ive done it both with skiving right up to the stitch with the stitch still being in full thickness leather. This seems to work well, except doesn’t like to spread evenly, or run through the double needle guide well. When ive skived the edge to sew in the skived area, its easier to fold and lay over, but im nervous of the strength of the seam, and the thin material doesnt feed through my machine well. It will have a tendency to bunch up, particularly in the start and stop when back tagging. I've never skived double the salvage width. I just assume it will be equally difficult to stop bunching, and i dont think when folded over that the two skived layers will equal the thickness of the unskived leather, leaving a ridge away from my seam width of my salvage.

-

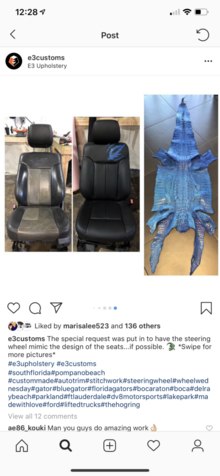

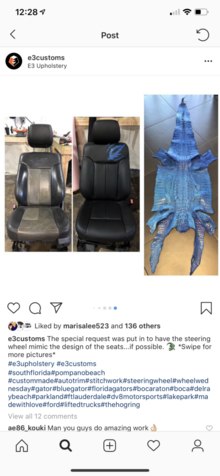

Working with gatorWe just recently added some gator to a F150 seat kit as a tribute to the customers late husband. It was very stiff and tough to work with, the spine is solid bone and would be uncomfortable in the seating area. Also watch out for it hitting the foot or needle of your sewing machine. We only used it as accent pieces, and any other time we’ve done gator print on seats or doors it has been embossed vinyl, or cow leather. Good luck!

Lee Welk

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring