-

Landon Zabloski

14Hello everyone,

Landon Zabloski

14Hello everyone,

I am looking to gather opinions and ideas about the Juki 1508NH sewing machine.

Currently I use a Consew 226R-1, which has treated me very well so far, but I am looking to upgrade. A few of the shortfalls I have noticed with my own machine are the tiny bobbin size, the relatively small maximum stitch length, and the fact I cannot sew with the big 207 thread without a lot of tinkering and issues. One other complaint I would have about my Consew is that when I am sewing and come to a seam "bulk", I really have to slow way down, use my knee lift carefully and feather the machine just to keep the stitch length uniform. I am sure that some of my issues are due to my lack of experience, but I also can't help but think a machine upgrade may help to offset my shortcomings at least a tiny bit.

With all that being said, I have researched many machines, and although there are so many great machines I am fairly set on the Juki 1508NH.

What I would like to know is;

1- Does anyone have one of these machines, if so how do you like them? Do you have any complaints about them?

2- The Juki literature mentions a "rectangular" feed locus that supposedly greatly improves the consistency of the stitch length even through bulky materials, does anyone have an opinion or first hand experience with this as it compares to other machines?

3- Lastly, I just noticed that NC makes their own version of the 1508NH which actually seems like it has more features and a far lower cost. I am curious to know if the NC version of the 1508 also has the "rectangular feed locus"? I know NC is a Hog Ring Supporter, so hopefully one of their reps can answer this one. I am Canadian so I would love to save money anywhere I can...seeing as how 1 Canadian Dollar is about 38 cents US....and then shipping to Canada is more expensive than to the Galapagos Islands.

Thanks in Advance for your help and opinions.

-Landon Zabloski -

Nadeem Muaddi

86Hey Landon,

Nadeem Muaddi

86Hey Landon,

You should reach out to Mal Maher, CEO of NC Carpet Binding & Equipment. He's a super nice guy and knows everything there is to know about industrial sewing machines. He can definitely point you in the right direction.

If you do wind up buying an NC machine, ask about their 12-month, 0-interest financing. It's an amazing deal.

Nadeem -

Landon Zabloski

14Thanks Nadeem that is probably exactly the tip I need to get my answers. I saw the article about the NC deals a few months ago on THR and thats what led me to find their version of the 1508 so I will be very interested to find out more when I contact Mal.

Landon Zabloski

14Thanks Nadeem that is probably exactly the tip I need to get my answers. I saw the article about the NC deals a few months ago on THR and thats what led me to find their version of the 1508 so I will be very interested to find out more when I contact Mal.

Thank you again for this Forum and your help! -

Steven M

3If it's in the budget, I highly recommend either a Durkopp M-Type or for a LOT less, the Juki LU-2810A-7. It has a high step mode that is selectable at the push of a button to high-step the foot, along with auto back tack and thread trimmer. Well worth the expense. It will dramatically improve your output. -

Landon Zabloski

14Steven,

Landon Zabloski

14Steven,

Thanks for those suggestions! The M-Type would be a bit outside of my price range. I found it for about 7k USD which converts to about 93k in our Hockey money.

The Juki 2810 is much closer to my budget though and it definitely has features I hadn't even considered. I seem to remember reading a post in the old forum where you had just purchased a few machines, is that the model you have? Also do you know if its got a longer throat than the 1508? I would love a little more room to work with.

Thanks very much for the input I really appreciate it.

-Landon Z -

Mal Maher

8Hello Landon good morning. We have Juki 1508 units in stock and sell them with regularity. Our family has resold all Juki style machines for many years. I have been waiting on more information from them pertaining to the 'Feed Locus' but at this stage, I know about as much as everyone else does. Our NC1508 provides a low cost alternative and is equipped with an exclusive foot control knob as illustrated on our site. Both units will allow you to sew with 207 and thick/multi-ply applications with ease. These units are 'vertical axis' walking foot machines and have big bobbins. I'm guessing your old 226 is a small bobbin? If so, both units will provide a bigger bobbin capacity, reverse, auto oiling, and a servo motor. Either unit will be an enormous upgrade over what your'e employing now.

Mal Maher

8Hello Landon good morning. We have Juki 1508 units in stock and sell them with regularity. Our family has resold all Juki style machines for many years. I have been waiting on more information from them pertaining to the 'Feed Locus' but at this stage, I know about as much as everyone else does. Our NC1508 provides a low cost alternative and is equipped with an exclusive foot control knob as illustrated on our site. Both units will allow you to sew with 207 and thick/multi-ply applications with ease. These units are 'vertical axis' walking foot machines and have big bobbins. I'm guessing your old 226 is a small bobbin? If so, both units will provide a bigger bobbin capacity, reverse, auto oiling, and a servo motor. Either unit will be an enormous upgrade over what your'e employing now.

Warranty: The NC unit comes with a 2 year limited warranty, Juki's we offer a 1 year limited warranty. This year at Sema, if purchased at the show, I will be offering a 5 year limited warranty on all NC Machines. Stay tuned for more on that and Sema Pricing.

Rectangular Feed Locus: Wish i knew more, but I have calls into Juki's technical lead.

Shipping: We forward our discounted shipping rate onto our clients. What is your postal code? I'd be happy to provide a quotation into Canada and surely save you there.

Link to these units and most NC interiors equipment. The only Juki's listed here are the 1508 and 1900: http://www.n-ccarpet.com/index.php?route=product/category&path=16000 -

Mal Maher

8Thank you Nadeem. We'll do all we can to earn your business and provide support for years to come.

Mal Maher

8Thank you Nadeem. We'll do all we can to earn your business and provide support for years to come. -

Nadeem Muaddi

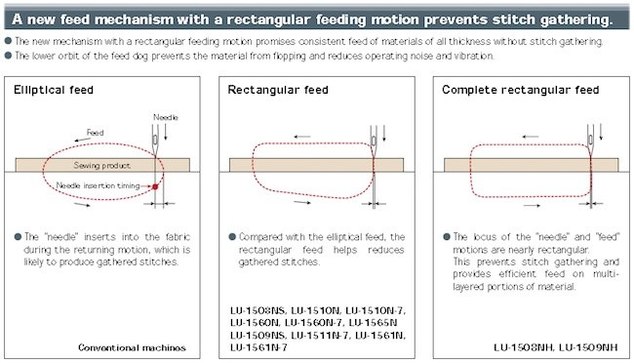

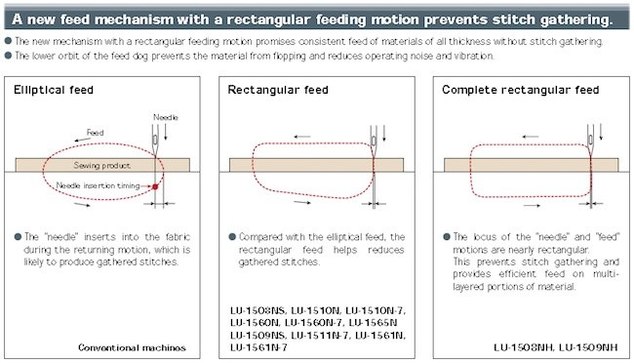

86An engineer at Juki sent the following graphic along to NC to share with you. It illustrates the Juki 1508NH’s new feed mechanism.

Nadeem Muaddi

86An engineer at Juki sent the following graphic along to NC to share with you. It illustrates the Juki 1508NH’s new feed mechanism.

The primary difference between this new feed mechanism and the existing feed mechanism is (1) a longer stitch length, (2) rectangle feed, and (3) an altered needle bar stroke.

As you noted, NC sells the Juki 1508NH and the NC1508NH. The two machines are comparable, but the NC machine costs $1,000 less and comes with a longer limited warranty.

If you have any questions, give Mal a ring at 973-481-3500. He can provide you with more details. -

Mal Maher

8

Mal Maher

8

To be 100% clear on pricing:

Juki 1508N $2450

True Comparison:

Juki 1508NH $2850

NC1508NH $1850.....$1000 less than Juki 1508NH All three units are in stock and available to ship today.

If you can, wait until Sema to order machines. We're going to have the most aggressive offering in the history of our company. It will include additional savings, extended warranties, & more. You don't have to be at Sema to take advantage of the program. -

Andrew Bodnar

5I'd go with the NC. I had the juki 1541s it was complete garbage. Bought it brand new have had better luck with the 20 yr old Mitsubishi I bought to replace it. -

Jeremy caron

8I have a juki 1508nh. I love it, I regularly sew 207/270 thread without a problem. The biggest difference I noticed with the feeding mechanism is that the stitch length is really consistent around turns. I purchased mine form a well known Los Angeles sewing machine dealer, and the transaction was as easy as it gets. If I had one complaint, it would be the needle size. The machine uses a 190 series needle which is longer that's than the typical 135 series needles. I have noticed that you can get some deflection in the needle when sewing with multiple thick layers or through platic or wood. Not a huge problem, just seems I change needles more often than before. The machine can be adjusted to use the 135x17 needles pretty easy, but I haven't felt it was needed. Hope it helps!

Jeremy caron

8I have a juki 1508nh. I love it, I regularly sew 207/270 thread without a problem. The biggest difference I noticed with the feeding mechanism is that the stitch length is really consistent around turns. I purchased mine form a well known Los Angeles sewing machine dealer, and the transaction was as easy as it gets. If I had one complaint, it would be the needle size. The machine uses a 190 series needle which is longer that's than the typical 135 series needles. I have noticed that you can get some deflection in the needle when sewing with multiple thick layers or through platic or wood. Not a huge problem, just seems I change needles more often than before. The machine can be adjusted to use the 135x17 needles pretty easy, but I haven't felt it was needed. Hope it helps! -

Mal Maher

8Well said. We set our single needle units on the 135...but with a different point. Holds up better and causes less downtime, issues, etc.

Mal Maher

8Well said. We set our single needle units on the 135...but with a different point. Holds up better and causes less downtime, issues, etc. -

Mal Maher

8Hello Andrew good morning. Yes we do. Our family has been selling this unit for over 17 years. It's a tremendous machine and has a 30" inside sewing throat, extension reverse lever, big bobbin, and is self oiling. They're $4900 complete with a servo motor workstation. I can do $4500 delivered. No tax and no shipping to a commercial address. Direct link: http://www.n-ccarpet.com/index.php?route=product/product&path=16000&product_id=372

Mal Maher

8Hello Andrew good morning. Yes we do. Our family has been selling this unit for over 17 years. It's a tremendous machine and has a 30" inside sewing throat, extension reverse lever, big bobbin, and is self oiling. They're $4900 complete with a servo motor workstation. I can do $4500 delivered. No tax and no shipping to a commercial address. Direct link: http://www.n-ccarpet.com/index.php?route=product/product&path=16000&product_id=372

They're in stock and able to ship today. Mal @ NC 800-526-1184 -

Landon Zabloski

14

Landon Zabloski

14

Jeremy thanks for that info, I love the idea that the stitch length stays perfect around corners, that has always been a fight with my old machine. Also glad you mentioned the needle system, I was wondering if there was any pros or cons to the 190 style so that's nice to know. Do you find the stitch length stays nice and uniform when you go from sewing 2 layers to 4 over a seam? The NC1508 has that foot height switch that the Juki doesn't, do you think thats something you wish you had on your machine?

Thanks again for your reply!

-Landon Z -

Landon Zabloski

14

Landon Zabloski

14

Mal does this mean that the NC1508 would ship ready to use a 135 needle system? This machine keeps sounding more and more like what I am looking for. Im trying to find a shop near me I can go take a 1508 for a test run before I buy but it certainly sounds like this machine checks all the boxes for me.

Thanks again for answering all these questions I sure appreciate you taking the time out of your day.

-Landon Z -

Mal Maher

8Of course. We setup on the standard system with a heavier gauge & stronger/different point needle. Something we do that nobody in the nation does. Less issues and better penetration. $1000 difference is biggest advantage. Let me know and it'll ship today.

Mal Maher

8Of course. We setup on the standard system with a heavier gauge & stronger/different point needle. Something we do that nobody in the nation does. Less issues and better penetration. $1000 difference is biggest advantage. Let me know and it'll ship today. -

Justin L Rash

9I bought a Juki 1508N couple years ago when i first started and i love it. Never had any issues with the machine as long as it stays oiled and clean every so often. Bought from Keystone in PA. Owner had it set up to use 135x17 needles. Rarely have to change the needles. Don't think I'd ever use another machine unless it was an Adler

Justin L Rash

9I bought a Juki 1508N couple years ago when i first started and i love it. Never had any issues with the machine as long as it stays oiled and clean every so often. Bought from Keystone in PA. Owner had it set up to use 135x17 needles. Rarely have to change the needles. Don't think I'd ever use another machine unless it was an Adler -

Jeremy caron

8Yup, the 190 needle is so long it gets weak and starts to deflect towards the shuttle/hook. I always know it's time to change the needle because it will show up when I backstitch. The machine will sew over many many layers and the stitch length is very consistent. I may change mine to the 135 needle system after I use up all of my 190 needles. I like the idea of that 30" long arm machine Mal Mayer mentioned, I will be adding a long arm next year and I will make sure to take a closer look at that machine

Jeremy caron

8Yup, the 190 needle is so long it gets weak and starts to deflect towards the shuttle/hook. I always know it's time to change the needle because it will show up when I backstitch. The machine will sew over many many layers and the stitch length is very consistent. I may change mine to the 135 needle system after I use up all of my 190 needles. I like the idea of that 30" long arm machine Mal Mayer mentioned, I will be adding a long arm next year and I will make sure to take a closer look at that machine -

Landon Zabloski

14Im sure happy I posted the question about this machine, you guys have answered all the questions I had and more. To be honest I had no idea the machine could be converted to the 135 needle system, and then I found out from Mal at NC that their NC1508NH is set up already with the 135 system which kicks ass.

Landon Zabloski

14Im sure happy I posted the question about this machine, you guys have answered all the questions I had and more. To be honest I had no idea the machine could be converted to the 135 needle system, and then I found out from Mal at NC that their NC1508NH is set up already with the 135 system which kicks ass.

Last week I ordered the NC1508NH from Mal Maher at NC. I haven't received the machine yet, but I have to say that dealing with Mal at NC has been fantastic! He has bent over backwards to make it as easy a process as possible for me. Honestly the best customer service I have received anywhere. Shipping anything to Canada is usually a nightmare, Mal helped me out to make it super easy and gave me a few helpful tips to save me some money.

I am also pretty impressed that we can post a question about sewing machines here and end up dealing in person with the CEO of a major sewing machine manufacturer. Thanks again THR, this site is such a valuable resource for me. I can't thank the staff and contributors enough.

When I get my new machine I will be sure to do a review and maybe a side by side comparison to my old Consew in case it may help someone else who is machine shopping.

If anyone is looking for a new machine, I would highly recommend talking to Mal at NC, especially with the SEMA deals they will be offering, I personally couldn't find a better value anywhere.

-Landon Zabloski -

Nadeem Muaddi

86That's so awesome Landon! So glad we were all able to help you, and that you ended up choosing the best machine for you and your shop.

Nadeem Muaddi

86That's so awesome Landon! So glad we were all able to help you, and that you ended up choosing the best machine for you and your shop.

Mal and the entire NC team are amazing. Always helpful, and stand behind every machine they sell. We love working with them.

Looking forward to that review! -

Mal Maher

8Wow thank you for posting this wonderful feedback. Please let me know how you like the unit. Thus far, clients that have purchased them are quite happy. The biggest buyer runs them all day on marine seats/interiors and they've purchased 5 units since April. The $1000 savings/unit is what got our foot in the door with them. The truest proof of value is in the results and operator happiness. I'm hopeful you enjoy the machine and that it provides years of worry free sewing.

Mal Maher

8Wow thank you for posting this wonderful feedback. Please let me know how you like the unit. Thus far, clients that have purchased them are quite happy. The biggest buyer runs them all day on marine seats/interiors and they've purchased 5 units since April. The $1000 savings/unit is what got our foot in the door with them. The truest proof of value is in the results and operator happiness. I'm hopeful you enjoy the machine and that it provides years of worry free sewing. -

Mal Maher

8Thank you Nadeem & Naseem. Your site, network of upholsterers, & hard work have provided the industry with a true asset.

Mal Maher

8Thank you Nadeem & Naseem. Your site, network of upholsterers, & hard work have provided the industry with a true asset. -

Landon Zabloski

14So I received my new machine from NC last week, and I have had some time to get to know it so I wanted to share my opinion.

Landon Zabloski

14So I received my new machine from NC last week, and I have had some time to get to know it so I wanted to share my opinion.

First impressions, having never bought a new machine before I was very happy to find along with the machine I also got 2 quarts of machine oil, a toolkit, bobbins, box of needles, 2x 2000 yard spools of thread, spare brushes for the motor and a wicked pair of tweezers.

Assembly of the machine was super easy, apart from how heavy the head is compared to my old Consew 226. The 1508 is easily twice the weight of my old machine and is far beefier in all aspects. Going from my old machine to this unit being self oiling is a real treat. Not that oiling is a big pain but I suppose its a comfort feature that also gives me peace of mind.

The huge bobbin is one of my favourite upgrades, my old bobbins were so tiny I was constantly winding new bobbins and it drove me nuts.

I LOVE the stitch length adjustment dial, and the 10mm stitch length is so nice. My Consew 226 maxed out at about 5mm, which made factory looking seams almost impossible on seats like

In a King Ranch.

I am also a big fan of the presser height adjusting dial on the top of the machine. So handy when sewing along and coming up to some bulk. It is a very big feature I didnt even realize would be so convenient for me.

As mentioned before the customer service I received was a major selling point for me, I appreciate so much how helpful and thorough Mal was in responding to all my questions and requests. The price difference between this machine and a Juki is substantial at 1000 dollars, I have not used a Juki but I really cannot imagine it being worth the extra money, especially with the great warranty offer NC is throwing in for the SEMA special, and the fact the Juki doesn't have the presser foot lift adjustment like the NC1508 does.

This Machine goes through super thick material like nothing, I swear I could sew a bowling ball with it if I had to.

All in all I couldn't be more happy with my purchase, I highly recommend this machine to anyone who is in the market.

Cheers

-Landon Zabloski -

Nadeem Muaddi

86That's awesome Landon. You need to show us photos of the first major project you do with this machine!

Nadeem Muaddi

86That's awesome Landon. You need to show us photos of the first major project you do with this machine! -

Mal Maher

8Thanks so very much Landon. I am blown away by the time and effort you put into this review. All the best with it and we'll be here to back it up.

Mal Maher

8Thanks so very much Landon. I am blown away by the time and effort you put into this review. All the best with it and we'll be here to back it up. -

Joe Scarlavai

1@Mal Maher do you have a double needle machine available? I've been trying to get my boss to send me to SEMA and we are about to buy one so this might be the selling point to him haha

Joe Scarlavai

1@Mal Maher do you have a double needle machine available? I've been trying to get my boss to send me to SEMA and we are about to buy one so this might be the selling point to him haha -

Mal Maher

8Hi Joe. Yes we will have both of our twin needle mahine and twin needle long arm st Sema. Here's a link to all our units. The savings will be quite substantial. If this is something you need to purchase now please call the office 973-481-3500. Thank you very much for inquiring. I look forward to meeting you at SEMA where are you can try all the machines. http://www.n-ccarpet.com/index.php?route=product/category&path=16000

Mal Maher

8Hi Joe. Yes we will have both of our twin needle mahine and twin needle long arm st Sema. Here's a link to all our units. The savings will be quite substantial. If this is something you need to purchase now please call the office 973-481-3500. Thank you very much for inquiring. I look forward to meeting you at SEMA where are you can try all the machines. http://www.n-ccarpet.com/index.php?route=product/category&path=16000

Click on the unit of your choice for in action video and for details

Welcome to The Hog Ring!

This forum is only for auto upholstery pros, apprentices and students. Join today to start chatting.

More Discussions

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring