-

Bill Gordon

1I’m working on a 64 Sport Fury convertible replacing everything, any tips? I’ve done a lot of tops several years ago but never one like this on an old car. There’s no rear deck tack strip, everything is held in place by the narrow trim over the body. No tack strip on the header either, just glue with the gasket channel over it. I’ve got the window looking good and am starting to fit the top.

Bill Gordon

1I’m working on a 64 Sport Fury convertible replacing everything, any tips? I’ve done a lot of tops several years ago but never one like this on an old car. There’s no rear deck tack strip, everything is held in place by the narrow trim over the body. No tack strip on the header either, just glue with the gasket channel over it. I’ve got the window looking good and am starting to fit the top. -

Fred Mattson

152Make sure that the gluing surface is clean before you apply new contact cement. Apply the contact cement to both mating surfaces and then wait for the glue to flash, otherwise it will not stick properly and yo will have a hard time getting the material to stay in place.

Fred Mattson

152Make sure that the gluing surface is clean before you apply new contact cement. Apply the contact cement to both mating surfaces and then wait for the glue to flash, otherwise it will not stick properly and yo will have a hard time getting the material to stay in place.

If you need to make an adjustment to the top to relieve wrinkles, always re apply glue to assure a good bond.

Good Luck and please post pictures of the finished project. -

Eric Gordon

41Once the curtain is in place with a proper bow height , I suggest to glue the 1/4 top flap around the 1/4 frame . This will allow you to have the top positioned in a way so as to line up the top toward the belt line. Always check that the roof is centered as you are fitting. Also, I do have to say you have a good last name.

Eric Gordon

41Once the curtain is in place with a proper bow height , I suggest to glue the 1/4 top flap around the 1/4 frame . This will allow you to have the top positioned in a way so as to line up the top toward the belt line. Always check that the roof is centered as you are fitting. Also, I do have to say you have a good last name. -

Bill Gordon

1Thanks for the advice, this one has me a little on edge. There are no guide marks on the top (Electron) and very little wiggle room for adjustments. I’ve used the old top to get an idea for fitting it. Right now the rear bow height is about 1/8” long... I just hope it doesn’t move much more after stretching it forward

Bill Gordon

1Thanks for the advice, this one has me a little on edge. There are no guide marks on the top (Electron) and very little wiggle room for adjustments. I’ve used the old top to get an idea for fitting it. Right now the rear bow height is about 1/8” long... I just hope it doesn’t move much more after stretching it forward -

Eric Gordon

41Yes, Mopars through these years had a unique installation method. Gluing the 1/4 flap in place first will put the top in the correct position. By pulling the top rearward over the rear bow and fitting to the belt line, it will allow the roof to fit without a concern that the bow will move out of position. Using steam will help in the installation

Eric Gordon

41Yes, Mopars through these years had a unique installation method. Gluing the 1/4 flap in place first will put the top in the correct position. By pulling the top rearward over the rear bow and fitting to the belt line, it will allow the roof to fit without a concern that the bow will move out of position. Using steam will help in the installation -

Robert Webb

16This is actually an easy top to do seeing as its an outside mount( much like doing a vinyl top) Get your rear bow height dialed in and lock it in place with some 1 inch webbing. Center and staple the top of the window first leaving appropriate room for zipper if equipped. I always mark on the body the holes that are for the molding as opposed to the mounting screws. Pull window down and set some screws. Now lay top over frame and center over rear window. As others suggested glue quarters for now. I then staple top to rear bow above window if I am confident in its location. Now you can play with and set rear bound edge of top to the body. Fill in the side quarter with screws. You should be good from here.

Robert Webb

16This is actually an easy top to do seeing as its an outside mount( much like doing a vinyl top) Get your rear bow height dialed in and lock it in place with some 1 inch webbing. Center and staple the top of the window first leaving appropriate room for zipper if equipped. I always mark on the body the holes that are for the molding as opposed to the mounting screws. Pull window down and set some screws. Now lay top over frame and center over rear window. As others suggested glue quarters for now. I then staple top to rear bow above window if I am confident in its location. Now you can play with and set rear bound edge of top to the body. Fill in the side quarter with screws. You should be good from here. -

Bill Gordon

1Ok, the top is on and looks pretty good (I’m doing this job as I have time to work on it). One more question, there’s an inside flap on the quarter panels about 4” wide and 4” long which is loose facing up. It’s above the molding line and I see nothing it should be attached to. The old top didn’t have anything like this. It’s an Electron top. Thanks again for your advice. I’ll be finishing this up Sunday...wedding in the NC mountains tomorrow and they’re forecasting 1-3 inches of snow!!

Bill Gordon

1Ok, the top is on and looks pretty good (I’m doing this job as I have time to work on it). One more question, there’s an inside flap on the quarter panels about 4” wide and 4” long which is loose facing up. It’s above the molding line and I see nothing it should be attached to. The old top didn’t have anything like this. It’s an Electron top. Thanks again for your advice. I’ll be finishing this up Sunday...wedding in the NC mountains tomorrow and they’re forecasting 1-3 inches of snow!! -

Eric Gordon

41If I remember correctly, that 4" area at the 1/4 does not attach to the belt but drops down into the 1/4 and gets a flat plate screwed onto it to hold it against the inner well panel. If there's a sewn flap that piece covers(drapes over) the screwed on flat plate. This drop in section at the 1/4 is needed so the top can be folded down.

Eric Gordon

41If I remember correctly, that 4" area at the 1/4 does not attach to the belt but drops down into the 1/4 and gets a flat plate screwed onto it to hold it against the inner well panel. If there's a sewn flap that piece covers(drapes over) the screwed on flat plate. This drop in section at the 1/4 is needed so the top can be folded down. -

Bill Gordon

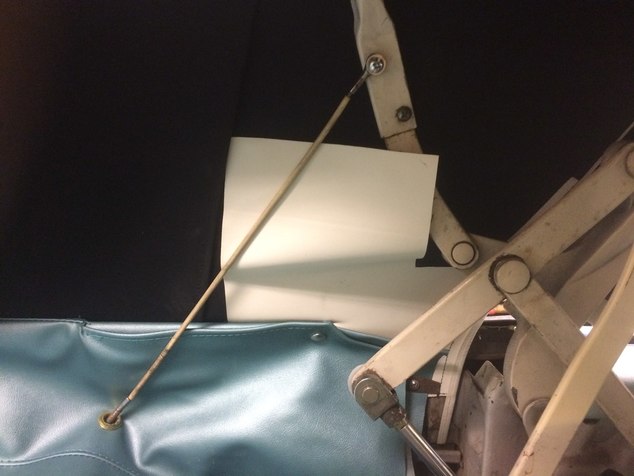

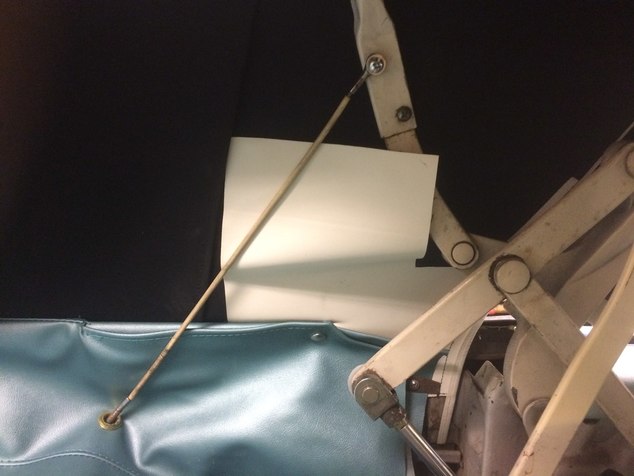

1

Bill Gordon

1

The top is done except tor a couple screws and sticking the rubber back in. For being out of practice it came out good. Here’s that flap I was talking about, any ideas of what it’s for and what to do with it? It’s fastened to the top open upwards. -

Robert Webb

16Like Eric said it goes under the well liner and gets screwed to the body with a small metal strip. You could fab one out of abs or most anything. Just extra rain protection

Robert Webb

16Like Eric said it goes under the well liner and gets screwed to the body with a small metal strip. You could fab one out of abs or most anything. Just extra rain protection

Welcome to The Hog Ring!

This forum is only for auto upholstery pros, apprentices and students. Join today to start chatting.

More Discussions

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring