-

Hal Bast

13I am looking to buy a skiver machine and need a little advice on which one to get. I have looked at several and they all seem to be the same, just different name brands. Maybe I'm overlooking something but I really don't see much difference except the price. My guess they are all made in China and each company puts the company name on it. Any help would be appreciated. Thanks

Hal Bast

13I am looking to buy a skiver machine and need a little advice on which one to get. I have looked at several and they all seem to be the same, just different name brands. Maybe I'm overlooking something but I really don't see much difference except the price. My guess they are all made in China and each company puts the company name on it. Any help would be appreciated. Thanks -

Keith Mayne

38I have the global branded one, unfortunately I can't tell you how well it works as skiving machines are notoriously difficult to set up and I haven't managed yet.I have an engineer coming in a couple of weeks to set it up and show me how to work it.

Keith Mayne

38I have the global branded one, unfortunately I can't tell you how well it works as skiving machines are notoriously difficult to set up and I haven't managed yet.I have an engineer coming in a couple of weeks to set it up and show me how to work it. -

Nadeem Muaddi

86@Hal Bast You should reach out to @Mal Maher at NC Carpet Binding & Equipment. They just introduced a new skiver to their product line that's getting great reviews from upholstery shops across the industry -- including Bux Customs and JK Automotive Designs.

Nadeem Muaddi

86@Hal Bast You should reach out to @Mal Maher at NC Carpet Binding & Equipment. They just introduced a new skiver to their product line that's getting great reviews from upholstery shops across the industry -- including Bux Customs and JK Automotive Designs.

The SK2019 is an industrial strength machine that can skive into leather up to 2". It comes with a servo motor workstation, 2-year. limited warranty and free LTL truck freight. If I'm not mistaken, they're also offering limited-time special on pricing too. You can view it here: https://bit.ly/2CKc5n9

Mal's a great guy, he'll tell you everything you need to know about these machines. -

Mal Maher

8Thank you very much Nadeem. I'm happy to offer Hog Ring Members a deal on our new Skiver. $1600 delivered. No Tax, No Freight & we'll set it up with the vacuum hookup with cutout. This will remove all excess leather from your unit. The unit will arrive with a fully assembled servo motor workstation. 2 year ltd. warranty. www.nccarpet.com

Mal Maher

8Thank you very much Nadeem. I'm happy to offer Hog Ring Members a deal on our new Skiver. $1600 delivered. No Tax, No Freight & we'll set it up with the vacuum hookup with cutout. This will remove all excess leather from your unit. The unit will arrive with a fully assembled servo motor workstation. 2 year ltd. warranty. www.nccarpet.com -

Gareth Judd

12Most if not all will be a copy of a italian brand, like swing machines you have to look past it to a certain degree.

Gareth Judd

12Most if not all will be a copy of a italian brand, like swing machines you have to look past it to a certain degree.

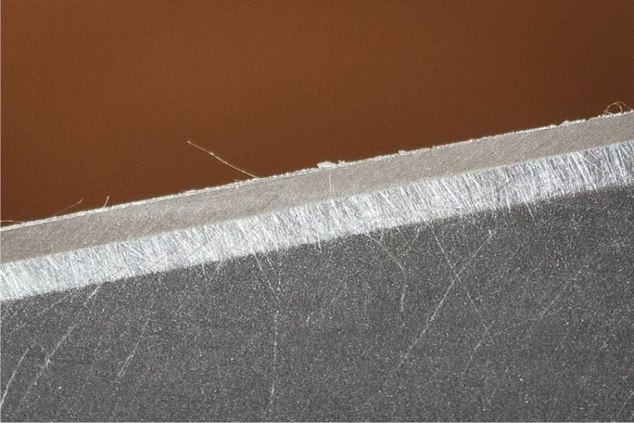

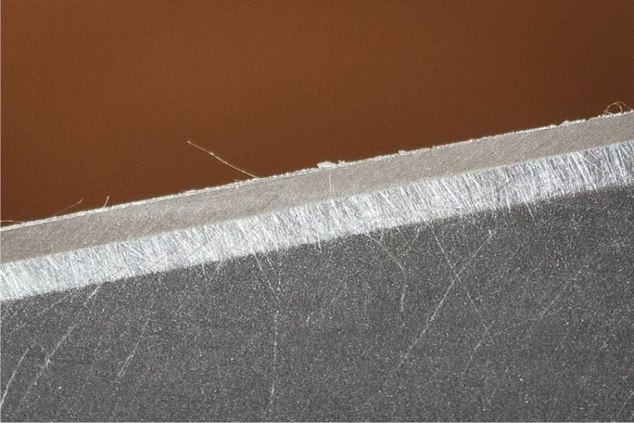

The absolute key to a skiving machine is blade sharpness! the grinding stone running true and deburing the inside of the bell knife!

every leather will need setting up different so learning the machine will take time and time to understand the machine BUT as above that knife must be keeper sharp not only for operation but for setting up -

Gareth Judd

12is your machine new? if so you will need to grind the knife down slowly so it has the curve of the grinding stone not a 30 degree (ish) angle they come with, running a marker pen on the bade with let you know when its the right shape

Gareth Judd

12is your machine new? if so you will need to grind the knife down slowly so it has the curve of the grinding stone not a 30 degree (ish) angle they come with, running a marker pen on the bade with let you know when its the right shape -

Keith Mayne

38No it was secondhand,previously used for making leather wallets and bags.I did use a sharpie on the blade ,mainly to check that it was sharpened all round.I've seen loads of setting up videos, read most setting up instructions and asked on several forums but I just can't get it dialled in.I've moved the blade in and out, the stone up and down, adjusted the pressure springs on the stone (both tilt and up/down) but it just seems to cut too much or not enough, I can't get the fine adjustment.No one at our shop has used one before so getting someone who hopefully knows what their doing will be a benefit otherwise I've just got an expensive space filler.

Keith Mayne

38No it was secondhand,previously used for making leather wallets and bags.I did use a sharpie on the blade ,mainly to check that it was sharpened all round.I've seen loads of setting up videos, read most setting up instructions and asked on several forums but I just can't get it dialled in.I've moved the blade in and out, the stone up and down, adjusted the pressure springs on the stone (both tilt and up/down) but it just seems to cut too much or not enough, I can't get the fine adjustment.No one at our shop has used one before so getting someone who hopefully knows what their doing will be a benefit otherwise I've just got an expensive space filler.

-

Jens Jesberg

50I've been trying for days to find the time to post a manual with a few pictures to help you possibly. But at the moment I have so much time pressure that I just can't make it.

Jens Jesberg

50I've been trying for days to find the time to post a manual with a few pictures to help you possibly. But at the moment I have so much time pressure that I just can't make it.

I've been trying for days to find the time to post a manual with a few pictures to help you possibly. But at the moment I have so much time pressure that I just can't make it.

the most important in a nutshell (point 5 is often forgotten):

1. the knife as far as it goes to the front

2. move the transport roller upwards as far as possible

If the position of the knife or whetstone is changed, the blade must be completely sharpened again. (When moving the blade after the sharpening stone always starts at the back of the blade.)

Before each sharpening, mark at least 1/2" of the blade surface with a permanent marker. Loop until no more colour is visible in the tip (in case of doubt, do not use a magnifying glass).

5. take a sharpening steel (depending on use) at regular intervals (with me every 3 - 6 months or after moving and then sharpening the blade) and hold it on the inside of the blade. This removes edges that can occur during sharpening.

-

Keith Mayne

38Had mine set up and it seems to work a treat now.Test pieces skived great, next piece I tried was dash piece and found machine was great at skiving a chunk out of my finger, it also skived the panel nicely.

Keith Mayne

38Had mine set up and it seems to work a treat now.Test pieces skived great, next piece I tried was dash piece and found machine was great at skiving a chunk out of my finger, it also skived the panel nicely.

Welcome to The Hog Ring!

This forum is only for auto upholstery pros, apprentices and students. Join today to start chatting.

More Discussions

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring