-

Matt Sonnenburg

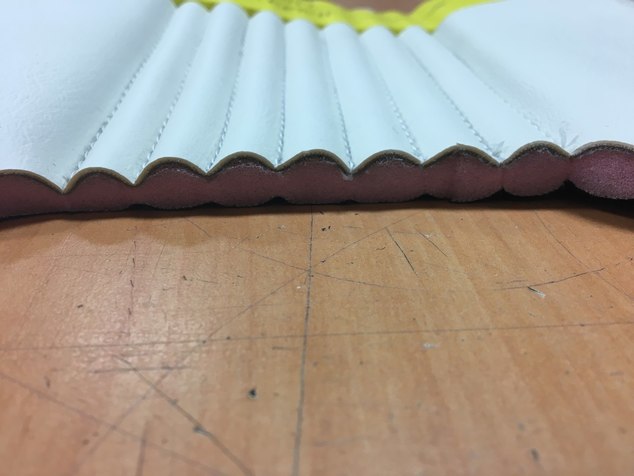

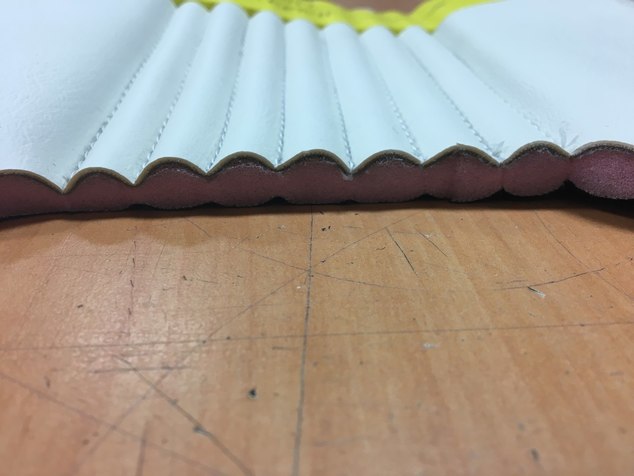

15So sewing a lot of pleats in marine vinyl with foam backing. This has happened before, the foam side makes a nice raised pleat. Meaning the stitch sits in a valley but the vinyl side doesn't much. I tried using some strips of 1" twill on the foam side with no real change. The pleats seams are 1/2" apart.

Matt Sonnenburg

15So sewing a lot of pleats in marine vinyl with foam backing. This has happened before, the foam side makes a nice raised pleat. Meaning the stitch sits in a valley but the vinyl side doesn't much. I tried using some strips of 1" twill on the foam side with no real change. The pleats seams are 1/2" apart. -

Adam Gabriel

16What Darren said. You'll need to glue or apply a backing on that foam.

Adam Gabriel

16What Darren said. You'll need to glue or apply a backing on that foam.

Just like your scrim foam has, Brushed Tricot "T-Shirt" backing -

Matt Sonnenburg

15I was using some inch twill tape. The two seams are just a 1/2 inch apart. I grabbed some other material remnants I had and got it to work better. I am still getting a better raised section on the back side versus the front.

Matt Sonnenburg

15I was using some inch twill tape. The two seams are just a 1/2 inch apart. I grabbed some other material remnants I had and got it to work better. I am still getting a better raised section on the back side versus the front. -

Eric Gordon

41

Eric Gordon

41

I've used this method which seems to work well on very narrow pleats. Glue 1/2" pad onto bowlining which strengthens the padding and will stop it from stretching. Mark your lines on the vinyl to 5/8" for 1/2" finish allowing the stretch of vinyl to go side to side on the pleat. This allows the narrow pleat vinyl to stretch over the foam when sewn. Glue the vinyl onto 1/8" pad. Lay on top of foam (no glue) and sew.

Welcome to The Hog Ring!

This forum is only for auto upholstery pros, apprentices and students. Join today to start chatting.

More Discussions

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring