-

Elizabeth Hill

1I have a new interior project on deck which I’m pretty excited about, it’s a 50 Ford 2D sedan that the guy wants to turn in to a police looking car Black & White the whole nine yards. he’s a retired local county cop, I haven’t seen the total car yet but he did drop the seats off and while taking them apart the frames are pretty rusty and broken and they will need lots of pieces replaced or if possible i would like to find a frame assembly. I have done some frame repair but not on this scale if I have to piece this thing together I found plenty of places that sell the coils and “zigzag springs” but I would rather go with a new spring frame for the front seats if at all possible, looking for suggestions on where to source this frame if it exists

Elizabeth Hill

1I have a new interior project on deck which I’m pretty excited about, it’s a 50 Ford 2D sedan that the guy wants to turn in to a police looking car Black & White the whole nine yards. he’s a retired local county cop, I haven’t seen the total car yet but he did drop the seats off and while taking them apart the frames are pretty rusty and broken and they will need lots of pieces replaced or if possible i would like to find a frame assembly. I have done some frame repair but not on this scale if I have to piece this thing together I found plenty of places that sell the coils and “zigzag springs” but I would rather go with a new spring frame for the front seats if at all possible, looking for suggestions on where to source this frame if it exists -

Fred Mattson

152The 1949-50 ford was referred to as the shoebox ford and this body style was the beginning of a whole new design era for the automobile industry.

Fred Mattson

152The 1949-50 ford was referred to as the shoebox ford and this body style was the beginning of a whole new design era for the automobile industry.

These seat frames are not difficult to recondition. Once you have the seat stripped down, message me if you need any assistance. I can help with any issue you may encounter. -

Eric Gordon

41You may also want to check Snyders Antique Auto Parts. If they don't have the spring pattern they can custom build or use an available spring pattern and retro fit it to the base frame

Eric Gordon

41You may also want to check Snyders Antique Auto Parts. If they don't have the spring pattern they can custom build or use an available spring pattern and retro fit it to the base frame -

Elizabeth Hill

1Thanks for the reply, I’ll have to check Snyder’s to see what they have, otherwise I may have to get some helpful hints from Fred, thanks again

Elizabeth Hill

1Thanks for the reply, I’ll have to check Snyder’s to see what they have, otherwise I may have to get some helpful hints from Fred, thanks again -

Jens Jesberg

50I do the most frame/spring jobs by myself. I bought some helpfull tools over the last years which make the job much easier. The only thig I dont do by myself is with the small coils with thin whire. Therefor I have a company I can order the common seatframes also with custom spezifications fitting on bodylenght and wheight.

Jens Jesberg

50I do the most frame/spring jobs by myself. I bought some helpfull tools over the last years which make the job much easier. The only thig I dont do by myself is with the small coils with thin whire. Therefor I have a company I can order the common seatframes also with custom spezifications fitting on bodylenght and wheight.

Here are some tools I use.

Great osborne tool for vertical bending of ZigZag-Springs (need 2 of them):

for bending Springwire:

clamps for attaching wires or springs/making a bypass (there is a special pliers for it but you dont need it necessarily

There are also some other clamps but i dont know where you can get them. They are smaller and are fixing the springs at the metalband frame. But I only have my own stock on hand. -

Fred Mattson

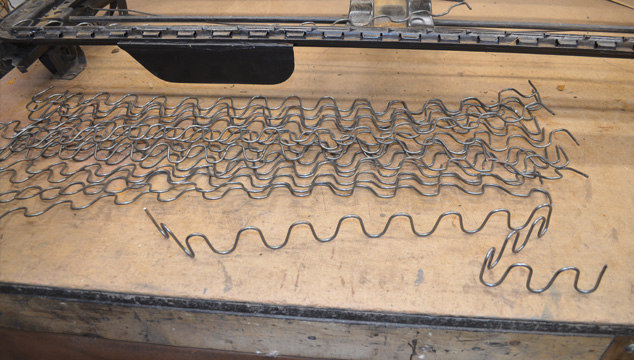

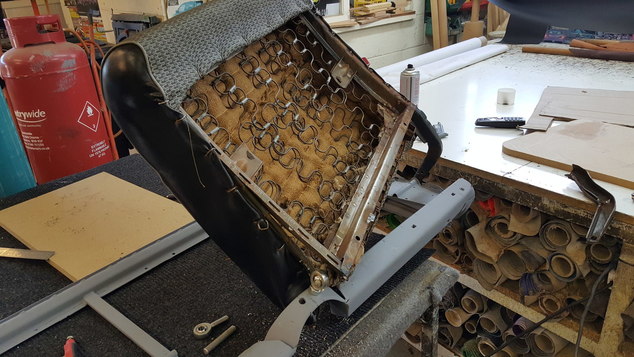

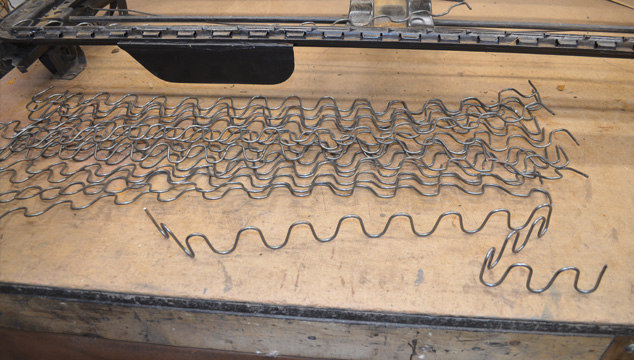

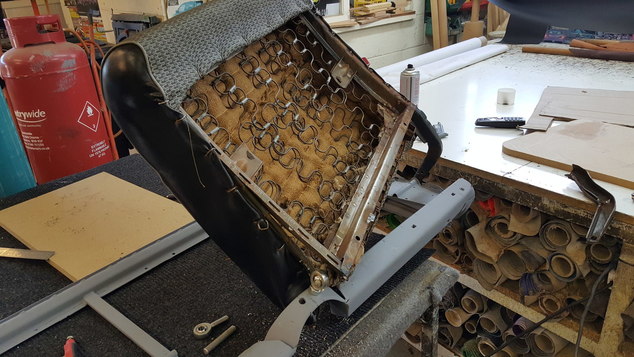

152I just finished this lower cushion last night. The lower spring set the customer provided was for a 1946/47 GM front seat and it did not fit this 1950 Cadillac frame. I had to make all new springs from 9 gauge roll stock. Each spring was hand bent and set.

Fred Mattson

152I just finished this lower cushion last night. The lower spring set the customer provided was for a 1946/47 GM front seat and it did not fit this 1950 Cadillac frame. I had to make all new springs from 9 gauge roll stock. Each spring was hand bent and set.

I almost hate to cover them with burlap because no one will be able to see them.

-

Chris Vining

48I did a 1950 chevy that had the body channeled over the chassis so much that the seat sat way to high so the only way I could do it was by making plywood base with elastic webbing over holes then soft foam so it still looked fat but the driver and passenger would sink down low when sat in .

Chris Vining

48I did a 1950 chevy that had the body channeled over the chassis so much that the seat sat way to high so the only way I could do it was by making plywood base with elastic webbing over holes then soft foam so it still looked fat but the driver and passenger would sink down low when sat in .

I even had to make a loop over the tunnel and fit rose joints to hinge back rest as the original hockey sticks had to be cut off

I did a 1950 chevy that had the body channeled over the chassis so much that the seat sat way to high so the only way I could do it was by making plywood base with elastic webbing over holes then soft foam so it still looked fat but the driver and passenger would sink down low when sat in .

I even had to make a loop over the tunnel and fit rose joints to hinge back rest as the original hockey sticks had to be cut off -

Naseem Muaddi

38That's a ton of work Fred. If only people understood the amount of prep work before you even start the upholstery

Naseem Muaddi

38That's a ton of work Fred. If only people understood the amount of prep work before you even start the upholstery -

Fred Mattson

152Thank you Naseem. This is why I post on this forum. I believe that the job should be done right. It may take a little extra effort, but it is well worth it in the end result.

Fred Mattson

152Thank you Naseem. This is why I post on this forum. I believe that the job should be done right. It may take a little extra effort, but it is well worth it in the end result.

I saw a post on another forum that the trimmer did a so-so job on a project because the customer did not want to pay too much. My thought is- "If you bid a project you should give your all to that project and not decide half way through it that your bid was too low and then skimp on quality just to blame the client for being cheap."

Everyone should learn from these mistakes and understand that you WILL loose on a project every once-in-a-while. This is what helps you become a better trimmer and your reputation will grow to reflect that. -

Eric Gordon

41Both Fred and Chris have shown us different techniques with excellent results. Great job. I suppose it depends on what the customer wants as well as their budget.

Eric Gordon

41Both Fred and Chris have shown us different techniques with excellent results. Great job. I suppose it depends on what the customer wants as well as their budget.

Welcome to The Hog Ring!

This forum is only for auto upholstery pros, apprentices and students. Join today to start chatting.

More Discussions

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring