-

Sabaspray thermo activated adhesiveGive them a call. They know who they sell their glue to

SABA Dealer

SABA North America LLC

2237 Wadhams Road Kimball, MI 48074.

+1 810 824 4964

USA -

How do you store your thread?Well...looks untidy, but I still know exactly which colors I have and which not :halo: :yum:

-

So-called "Corinthian Leather"Oh nice - I'm starting the first guess... I heard the term for the first time when I came into contact with the German HodRod scene. I first thought that the "to tuck" might be " stapling " because in German it sounds similar (tackern). And the production is like this. You first tuck (or sew, or stampl, or nail) the material and then roll it over.... -> tuck and roll.

-

How do you store your thread?So...and now I'm ashamed, and I'm not gonna show you how to store my thread on my "throw-it-in-shelf". :rofl: :halo: :sweat:

-

So-called "Corinthian Leather"Bonded Leather/Reconstituted Leather (in German "LEFA" - from the german Words of leather fibers ) comes to my mind immediately, because last week an unteachable customer brought me the "super quality" (quote customer).

I was too expensive for him to do his motorcycle seat... Now of course he had ruined the cushion with the grill knife and bought "real leather" on the internet. Now I should turn shit into gold again.:smirk:

Generally I find the approach good to recycle the leather waste further. However, it is of course not good to follow where the leather waste comes from and with which binders the fibers are then glued. Therefore I don't want to have this near my skin (clothes, belts, seats etc.).

The material I know as Leatherette is actually nothing more than vinyl - only thinner and inelastic. Similar to the very first vinyl from Skai which was used until the 50s.

vegan leather...thank god no spinner has asked me for "vegan leather" yet... I think I would puke in his face in a jet :vomit: :vomit: :vomit: .... Sorry - I have nothing against it if someone for reasons of the animal protection or the climate renounces meat products, but why must everyone therefore such a show do? And why is the soy stick that you put on the grill called "sausage"? :rage: :roll: ... But I digress... I am annoyed by the term "vegan leather" because, on the one hand, it is a stupid term and, on the other hand, it pretends false facts to the unknowing customer. For the convinced vegan, fabrics made of linen, jute, cotton, recycled fabric or other sustainable products are more helpful than vinyl. -

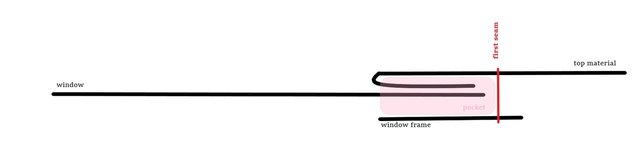

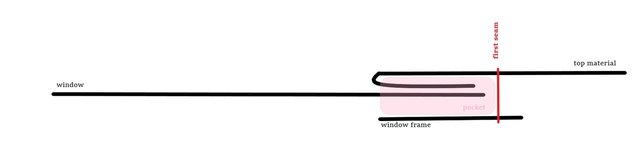

Almost hate to askIf you cut the window to the desired size and make the outer seam of the two seams as the first seam, then you have a "pocket" in which you can insert the window. But also here that it is much easier if you cut out the lower material later.

-

Almost hate to askDo you sew the ring from the inside or the outside? We call the ring " window frame " by the way. Do you have a technical term for it? When I make this kind of top, whether I make the top with the edge folded in or with piping, I don't put a ring under it. I take a complete piece of the desired material, which is ~ 2.5" larger than the window on all sides. Then I sew both seams from the outside. Then I turn the hood over and cut the material with the closed scissors. And you have a perfect ring - when you have sewn perfectly. When cutting out, it is important, as Gereth says, that you don't chop but push.

In most cases I use vinyl for the window frame for price reasons. -

Speaker CarpetI just got the sample card for this felt today. Actually intended for furniture, but here is a large selection of color

-

Toxic vinylI don't think there's any way to prove whether your spots come from vinyl or not. Still, I see it just like Cheryl does. We are exposed to toxins and unnatural influences every day. And we also have a pretty unhealthy job on the top of it. Many in our industry underestimate or ignore the danger - I catch myself again and again using the glue gun without breathing mask, using Chemials without gloves and so on. But many things are not cleared up and then we stumble over reports and examinations and only then get what you have done to your body over years.

You will, if you do a little research, quickly find suppliers who can offer you vinyl and leather where you minimize the risk that extreme toxins are contained.

For example, I have dealers who supply leather from German or European raw hides also tanned in german or european Tanneries. So I reduce the risk of hexavalent chrome in the leather. Not to mention the unworthy conditions for humans and animals as in leather production, for example in Bangladesh. With the artificial leather there are some which are free of BPA and other materials. look times for artificial leather the recommendations for kindergartens etc. have. Skai also has some of them in their program.

Here are 2 links for interested people... but partly nothing for weak nerves

leather

leather/textiles

Leider gab es keine englische Version davon - aber der Untertitel kann eingestellt werden. -

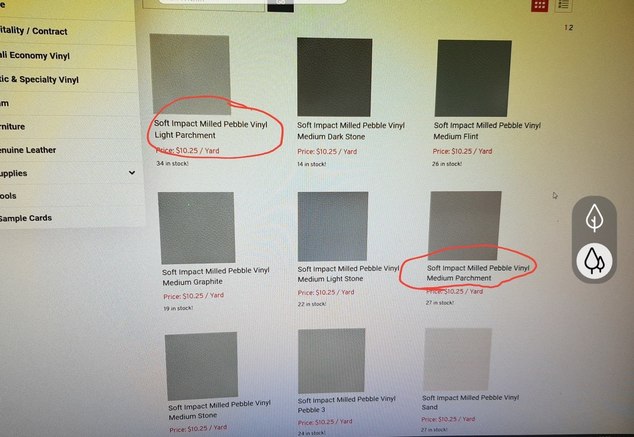

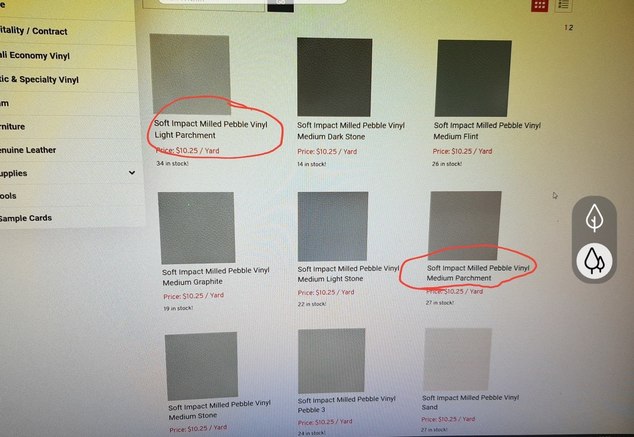

Color matchI have just searched the name of the collection on the Internet and my guess has been confirmed. There seem to be different colour gradations of the imitation leather. I've seen that with vinyl produced in America, there are colour shades like "light oak" "middle oak" "dark oak". Maybe you'll get a different shade.

I wouldn't do the back seat like that. You have to discuss this with the customer beforehand. Or tell him that the vinyl for the front seats is no longer produced.

Or you take a vinyl that has the same color but a different grain. For example "Valancia" grain instead of "Milled Prebble". Because for the eye matching colour is more important than matching grain.

You could also ask Torrie Coffman for help. Albright's Supply has the Soft Impact imitation leather in its program.

-

Color matchThe color deviation is already quite extreme. If the vinyl had been in use or had been in the party cellar where 15 people were smoking every evening, I would have said that it was the same. But batch deviations in vinyl aren't that extreme. I think the wrong color was sent to you. Do you know which manufacturer (Morben, Enduratex, Skai, ATN, Spradling etc.) the artificial leather is from? Some suppliers don't have the whole color palette of a supplier in their program but only a few selected colors. Then you could check it with the manufacturer of the vinyl. It is also possible that the supplier ordered wrongly or labelled wrongly.

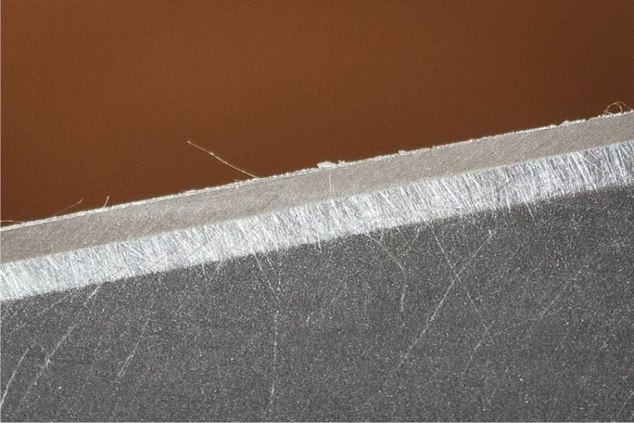

At least I haven't had such a colour deviation with vinyl yet. With leather yes - but this is also a natural product and is usually pre-treated in the country of origin. And the colour variations that are as strong as yours are also quite rare with leather...that has been the strongest I have had this year:

-

Recommendation for a supplier

Hi Ian!

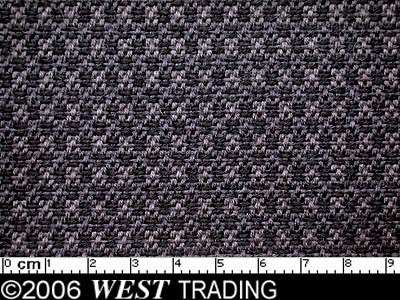

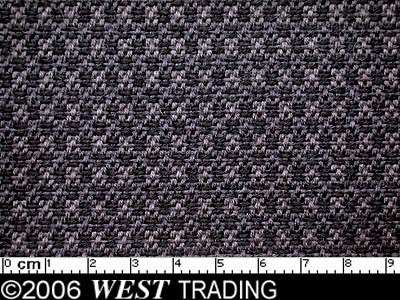

I am quite sure the fabric you're looking for is called "Kaffeebohne" ("coffee bean"). I suppose the color was black. Blue could also be, if the photo doesn't reflect the colour correctly. Don't be fooled by the look of the fabric. It's a wool fabric that's completely bleached out from the sun over the years (except for the "coffee beans", which keep their colour). If you cut the seams or look at the headrests from below you'll see it.

The best contact for Mercedes fabrics is Peter Steenbuck. He specialized in Mecedes years ago and has a good knowledge of the models, years of production and interior options. He also regularly has missing fabrics re-manufactured.

But you can also get the fabric from Westtrading.

But maybe you'll find a dealer near you if you know what you're looking for.

-

pressure pot pressuresI can't even say that. I work with an operating pressure of 6bar/87psi on all compressed air connections. For all other tools like the airbrush gun and the glue gun I adjust as needed.

I also use only one gun with one cup on the gun. For me, this turned out to be the best solution, because I often have to adjust the thickness of the glue to the different jobs and therefore always have to adjust the air supply and the amount of glue.

...So its all about the feeling :love: -

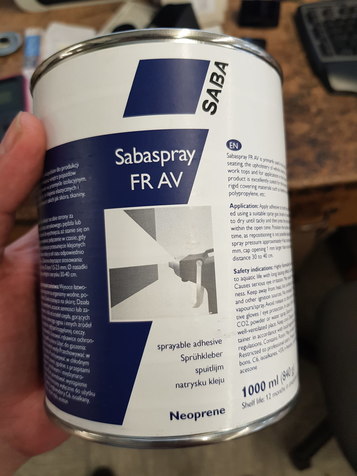

Steaming Leather@Mikael Romo

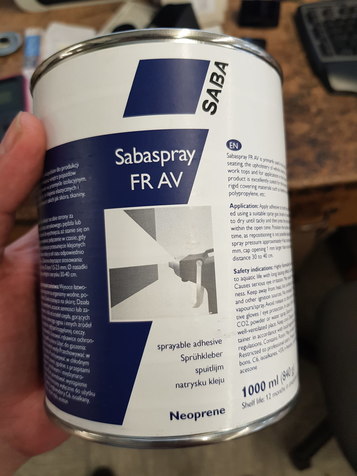

Its the Sabaspray FR AV. The glue is available in Germany in a red and a green colored version. The red colored variant is a slightly changed variant of a wholesaler who advertises that the red glue can be thermally activated......But the green variant can also, but it was never so explicitly advertised by Saba. In the beginning I also fell for this advertising strategy. Meanwhile I use the green glue which works just as well and costs me a little less. For some jobs the glue is a bit thick and I thin it with a bit of Sabaclean AV

-

Double needle sewing machineI currently have 3 double needle machines in use.

- 6mm (1/4") Paff 1246 flat

- 8mm (1/3") Golden Wheel post ...I don't know the number, but I think it's from the 8892 series.

-12mm (1/2") Adler 267 flat. For the eagles I still have a 10mm (3/8") set that I could build into the 267. Because the rebuild takes too long, I'm looking for a second 267.

I use the Adler and the Paff at the same table and if necessary simply change the machine, because I need the 12mm always only for a special order and would simply like to save me the place which the second table would take up.

I bought the Golden Wheel last year and wanted to give the cheap brands a chance. After all, the model only cost half the price of a comparable Adler.

The Golden Wheel is my first post sewing machine. I had to get used to sewing with the post. It's nice for a tight radius in the cover but for long straight seams its a bit annoying - but maybe it's also the missing exercise... Somehow I can't get the speed I want. That's why I'm building a little table that has the height of the post. So I can make a flat out of the post. -

Soft Top Windows@Amelia Brooker

I'm getting it from the MAH. But I think one of us will also know a supplier in Canada or USA where you can get it. But MAH certainly also ships internationally. If you don't get it tell me I have at least 70m left on the roll. -

Source for carpet snaps?@Tom Richardson

damn it... I was offline for a while. I could have sent you some. I always have them in stock. (But, they are not chrome plated but nickel plated.) Then you wouldn't have had to take 100. I also like to barter for black ones if you like. You can contact me if you are interested. Otherwise here is also the link to the company where I order. However, I do not know whether they send to the USA. -

Soft Top Windows@Amelia Brooker

The window in the picture is not glued. These windows are welded in a high frequency melting process. Seamless glued windows are very rare (at least with the European manufacturers). The Audi 80 and the Fiat Punto had such windows with the distribution. There was a kind of hot glue under in the window frame in which a copper wire was built in. You had to connect 12V to the copper wire to melt the glue for the installation and removal. For the installation one needed an original inner and outer frame to melt the new (mostly cursed expensive) windows in exactly the same way again. But even with the original frames, it didn't work with at least one of 5 windows. Because the wire at the start and at the end was hotter than in the middle. Either the window wasn't glued in the middle or - in the worst case - the convertible top was burned at the start and at the end.

With the welded windows as you posted them I sew in the new windows. But since the top has to be dismantled, you have to analyse the situation and condition of the soft top beforehand and talk to the customer about his car.

Of course, it is important how long the customer wants to drive the car? But even more important is how do you estimate the condition of the entire top. Have seams already dissolved? Are rubber bands or assembly strips damaged? You must be able to dismantle and mount the top without damage. Every customer thinks his top is "still good"... You have to stand up for it afterwards. Replacing the window is not worthwhile if the top is broken after one year.

I do it mostly in such a way that I ask the customer how long the window has lasted. And if I am of the opinion that the convertible top will last this time again, then I sew in a new window.

Also you should look what a new top costs. If it only costs a few hundred dollars it doesn't make sense either. Because the customer already pays the assembly costs - and in addition the material and the time for the sewing in or smaller repairs (1.5-2.5h) come still in addition.

The sewing is done as follows:

First I make marks on windows and window frames (the 2cm welding track). Then I cut out the window pane. I put the old pane on the new window pane.

You can also fix it with double-sided adhesive tape. But the tape must be removable without residue. I cut the new window to size beforehand but left it slightly larger.

Then I fix the top on the new window and make sure that the lines match those on the old pane. Then I sew in the window again with a special piping for windows (used at BMW Z3 for example). The piping has the shape of a "J" in the lateral profile so you don't look into the cut edge of the canopy fabric anymore. You should place the attachment of the piping in the middle of the window at the top, so that water can run in at the edge.

I hope you understand the translation :D

I try to post an pic of the piping tomorrow. -

I've Seen It AllSo basically jute is not such a bad material at all. it is very robust, durable material. And if I remember correctly even one of the few fibres that become more durable when wet.

The trend with the coffee sacks has never been able to establish itself here, but I have always had occasional requests. Recently I made a cover for a Harley bag. I did not find it so bad at all.

However I want to say quite clearly, an overturned bag is of course far from being a seat cover.

-

Foam shaping@Eric Gordon Great tip! Really good! I haven't seen that yet. I will try it at the next opportunity. If there is too much glue, the edge will be hard, but most of the time there will be a cushion over it.

I work with 3 different knife lengths with the Bosch foam saw. With it I cut everything into the rough shape. I do the finenesses with a compressed air grinder. If you've never done it before, it takes a little getting used to, but if you're used to it, you can get extremely fast.

-

Removing European glue residueIn most cases I only use a flexible brush which I bought especially for this work. with most headliners it goes pretty well. With scrapers or similar I always have the impression that the material is pressed into a kind of sticky paste. Sometimes I also take clear water with me. But only if the material is not too absorbent.

-

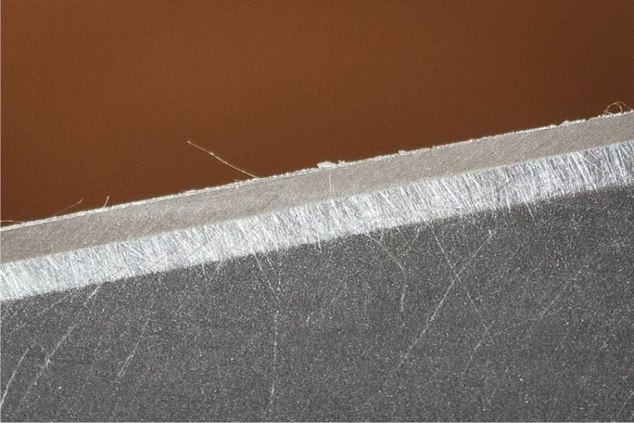

Skiver adviceI've been trying for days to find the time to post a manual with a few pictures to help you possibly. But at the moment I have so much time pressure that I just can't make it.

I've been trying for days to find the time to post a manual with a few pictures to help you possibly. But at the moment I have so much time pressure that I just can't make it.

the most important in a nutshell (point 5 is often forgotten):

1. the knife as far as it goes to the front

2. move the transport roller upwards as far as possible

If the position of the knife or whetstone is changed, the blade must be completely sharpened again. (When moving the blade after the sharpening stone always starts at the back of the blade.)

Before each sharpening, mark at least 1/2" of the blade surface with a permanent marker. Loop until no more colour is visible in the tip (in case of doubt, do not use a magnifying glass).

5. take a sharpening steel (depending on use) at regular intervals (with me every 3 - 6 months or after moving and then sharpening the blade) and hold it on the inside of the blade. This removes edges that can occur during sharpening.

-

Zig zag springs@Cody Lunning if the springs are still in good condition, you may not need to replace them at all. You may be able to bend them back into position (depending on the structure of the springs) by bending them up again. The easiest way is to use the right tool... 2 pliers also work.

but we had a similar topic one year ago. There I once posted photos to the tools. The tools are not exactly cheap but pay off pretty fast.

If you have the springs in position again, but notice that the spring effect has diminished a little, you can still pull burlap or something similar over the frame. This distributes the pressure on the springs better. I always do that, so that the cussion won't be pushed through the springs over the years.

The springs can also be connected to each other. You can take anything from cable ties to metal clips or wire. I bought this tool for a big order. With it the connecting goes damn fast. And it is cheaper and more durable than cable ties or similar.

Jens Jesberg

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring