Comments

-

Skiver adviceMost if not all will be a copy of a italian brand, like swing machines you have to look past it to a certain degree.

The absolute key to a skiving machine is blade sharpness! the grinding stone running true and deburing the inside of the bell knife!

every leather will need setting up different so learning the machine will take time and time to understand the machine BUT as above that knife must be keeper sharp not only for operation but for setting up -

Horseshoe seat cover

another example is this DB5 rear seat corner, with this i relive cut the horse shoe, pulled it straight where the corner is while machining the piping on and then machined it to the centre by doing this it gives the leather the natural shape of the seat BUT bear in mind this is stapled of around the back so i can manipulate the leather to suit.

with a front seat with piping down the side i would machine the piping to the face as above -

Horseshoe seat coveri would of machined the piping to the face and relive cut the corners, buy doing that you lock in the shape of the horse shoe keeping flutes straight, then machine the boarder , relive cutting as needed to hit your marks, this will give you a nice even bow all around the horse shoe. as you have it now your be fighting the cover

-

Skiving seams.i would suggest you lower your sew allowance, if you try and skive an edge at 10mm on auto leather across a dash its going to be hard work, your not going to get a even skive in my opinion,

you should be sewing in the skive so it folds clean (flat) with minimal salvage imo -

Porsche 964 roofHi jens thanks for taking the time to reply, i,ve actually found the colour and have a sample to hand, thumps up!

-

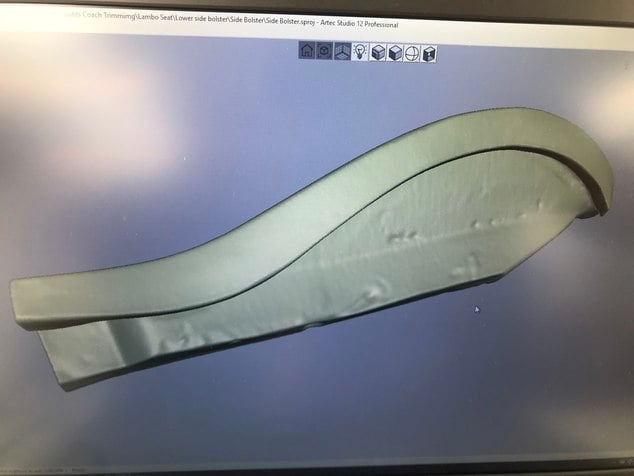

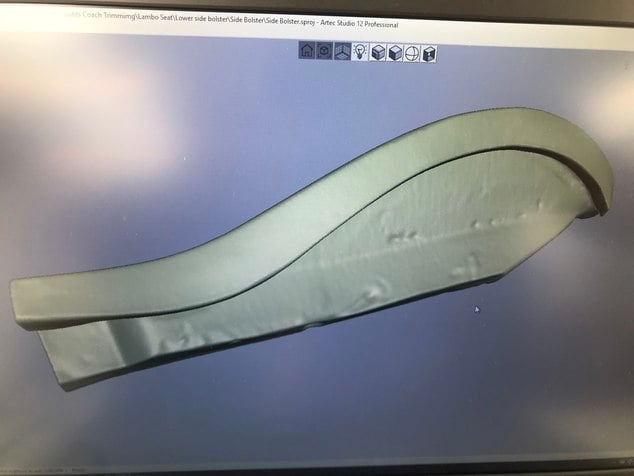

Show off your latest custom upholstery work.I hear ya but to make the moulds for the bolster involves 2 moulds per bolster due to the complexity plus the time for the pour foam trail and era, the foams are so hard machining them was a very good option (cost wise).

-

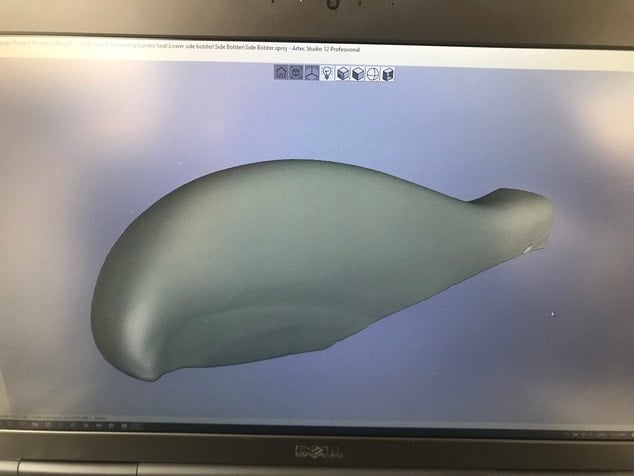

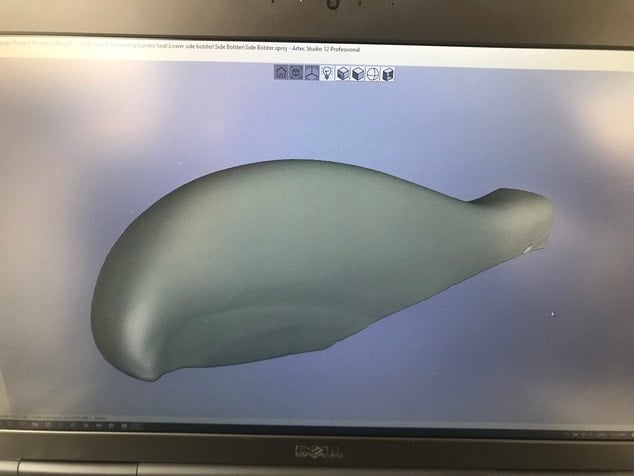

Show off your latest custom upholstery work.A new little process for me and something that worked out really really well so i thought i'd share. customer asked me to trim a pair of Lamborghini Diablo seat, had a look at the seats and they looked tired, baggy and used. When i removed the drivers base covers the original seat base bolsters foams where missing and a few sheets of foam in its place...this would explain the baggy cover and comfort problem! The customer expressed they need to look OEM and with the Diablo seat foams being hard to locate or NA a different angle was taken, so a call was made to a chap with a 3D scanner who scanned the inside passenger bolster foam which was in perfect condition which then can be mirrored for the oposite side and from there the foams where machined....Still a bit to learnt do but the foam shape are 100% perfect and fitted beautifully as the OEM foams did! super happy with the results and a avenue that will be explored!

-

stuffed cotton pleates.I would agree the base calico/muslim should be the finish size or taunt.

the calico/muslim controls the width and the structure of the tuck and roll, if you have 8mm extra on each pleat (2 inch) on the bottom there's nothing to governing the size of the flute apart from the stuffing? i think in a very short amount of time the flutes may look poor due to stretch? -

Air bag seatsLast time i phoned one of the larger oem thread manufactures for air bag thread i was asked a load of questions to which i had know idea!, as a result they didn't fancy selling me some thread lol (fair enough)

I do have some airbag thread and its not like cotton, polly or nylon..i think?, what its made of though or constructed i have no idea.

In the past when i was a employee we used to use a lighter gauge thread or air bag thread for new car retrims or repairs and never heard of a problem....

someone did do a video of a repaired seat (using a lighter thread i believe) and it deployed perfectly as you would assume really with the force they come out. -

Average amount of hours it should be takingI think the time scale thing is a bit pointless really unless your talking about the same make/model of seat, door card etc.

1 day (8 hours) to do front and rear seats isn't going to happen unless your talking 2 bench seats in perfect condition with only a few panels in them and crashing through them. -

Do you use a Serger in your shop?At a old place of work i used to work they bought one, we was doing very high end stuff and a new serger seemed the way to go...but in reality it didn't work out for what we was doing!

the machine would cut out the panel you marked (leather/foam) and whip them together which you would think speeds thing up but in reality it didn't, unless you need the machine to stop fraying in my eyes its not worth it. -

Sew foam questions for all the trimmersDepends on where you are but flutes to me are tuck and roll.

i use no glue just perimeter sew -

Merc style pleatsThe way your doing it is arguable the faster way, i still do them the merc way, straight onto calico and take out x amount from the calico.

im guessing your talking about w107 centres? That method won't work on some w113 and w111 flutes with the pinch in them i don't think.

Gareth Judd

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring