Comments

-

66 nova

sorry I was thinking about the trim with that last link i posted. I don't think that car has a traditional tack strip. It should be glue on all the way around. There should be some metal strips with the small triangular tabs/hooks if i remember correctly. Then once the liner is installed you would use the part (in the link from the previous post) on top just like a pinch weld molding/ snap on trim/ snap on windlace. -

Proposition 65After searching parts for customers, cars I've been seeing warning labels on the websites everywhere. It's a California thing... If you work in California you may want to stick every warning label known to man on everything you touch, just to protect yourself from frivolous law suits!

-

66 novaI'm pretty sure that car does not have the small trim part. If there is no screw hole between the top of the a pillar and windshield, then there is no trim that goes between. In that case just fold the raw edge under leaving a nice edge between the top of the pillar and windshield. If your liner has the pin holes just use a small piece of seam tape/double sided tape instead of gluing the material to itself.

I looked at pictures of a 66 i did a while ago there doesn't seem to be a screw hole.

-

glueing upholstery to absYou'll need to scuff the ABS first with either 80 grit paper or red scotch bright. You need a plastic adhesion promoter. I use SEM sand free at the very least use acetone. Then your preferred landau adhesive while the adhesion promoter or acetone is still wet. (some adhesion promoters are topcoat when dry just read label instructions)

If you are gluing the vinyl or leather finnished surface to the ABS (like a french seam) you'll want to use a brush on glue like HH-66, VLP, or plumbers cement for abs and plumbers all purpose I mainly use the all purpose for gluing seams

Also if you are using closed cell foam for padding always scuff the surface of the foam before you glue anything! -

Glue PotThat one looks fine but you will still need a separate regulator for the tank as explained above. if you have too much pressure on the tank it will force glue through the needle guide and make a huge mess everywhere.

I honestly don't the needle size will matter much. but I would go with the larger one. I think most of my guns are 1.8 -

Glue Pot

You'll want 2 separate regulators. The first with 2 outputs, output one will go to your glue gun air intake, output 2 will go to the secondary regulator, then the glue pot itself. Your main regulator the one you connect to your air compressor can be for normal shop air pressures. Your secondary regulator ( the one that regulates pressure on the glue pot) needs to be low pressure capable. Most regulators don't have low pressure capabilities I've been using this one with good results

I don't have the info in front of me but I think the highest tank/pot pressure should be no more than 13 psi. I run mine around 8 psi. when spraying thin foam glue (Dubois 301)

Same as

I built my own glue pot system, but with harbor freight paint pot The regulator from this paint pot system works well enough, just add your secondary regulator underneath, add a pressure relief valve, and another gauge so you can read the pressure on the tank, The most important part of the whole system is the relief valve. Just be safe!Warren McClung — Warren McClung

-

Dry Silicone?when I worked at a seating manufacture doing production sewing the seat cover installers used Stoner Urethane Mold Release

I would be careful with silicone I've heard that silicone is bad for plastic and vinyl surfaces. It is a big cause of many cracked dashboards being rubbed down with Armor All for years. (so I was told when attending Wyo. Tech.) I don't know this for sure but I don't take the chance. Its definitely not good to have in the air if you do any painting. -

Proposition 65I do the upholstery for a small fitness equipment manufacture. They ship machines to all 50 states and countries all over the world. I've never heard of the prop. 65 and I don't believe the manufacturer has either. I suppose this equipment isn't considered home or office furniture. Though many professional teams use this equipment in their gyms, it's also in tons of college and high school gyms. I just finished pads for 80 or so machines that went to Japan. None of the pads have warning labels. Again maybe it has something to do with the Furniture designation.

If you really need it, call you material supplier I'm pretty sure they have msds sheets on everything. Maybe they would know more about it anyway -

Split bench

Hey Chris, I was just scrolling through the pics you had in that link you provided. That is a great idea using the heim joints for the center backrest hinge pins. I'm going to put that one to use in the future. -

Panel Board Shelf above Upholstery TableI've worked out of my small 2 car garage for 15 years. I have many many things suspended from the rafters. The main thing when you do this is to be sure your rafters can take the extra load as they were not designed for that purpose. I reinforced mine with 3/8 cable to strengthen everything

small shop layout -

SharpiesMatt Sonnenburg — Matt Sonnenburg

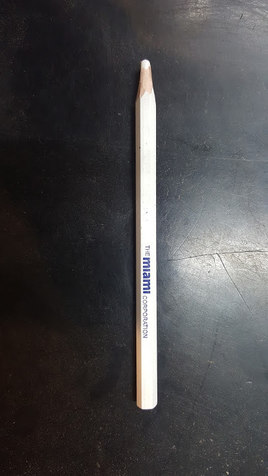

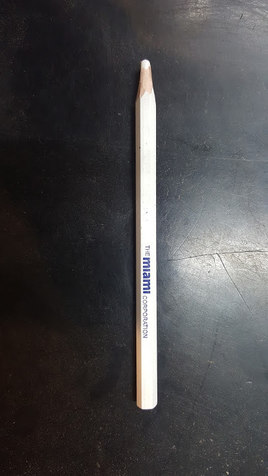

Just another thought. If you need to mark your sew foam, try a graphite construction pencil. I have used pencil to mark at times also. Though I'm not sure what it would to white thread if you sew through it., but you could test it out. Pencil generally wont mark well on the face of vinyl, but it works good on the backing. It works well when sewing tuck n roll when marking the back of the vinyl.

This white pencil from Miami works real good for marking the back of leather, vinyl, and cloth. I also use it for design layout on abs panels. They also have a blue fabric pencil but I have not used that one.

-

SharpiesI only use china markers to draw layout lines on the seat foam. In other words nothing that would be sewn through. I use the silver pens for marking vinyl and leather and chalk for cloth.

-

Rigid & flexible listing wiresThanksCesar Chavez — Cesar Chavez

I have done that before and it works well.

On the topic of listing wire I wonder if anyone has come across this stuff and maybe (fingers crossed) has a source for it. It's a Typar type listing with a pretty darn ridged plastic end. I pulled this out of the back seat of an Audi (I think) when I robbed the slide out cup holder from the cushion.

-

Seat carpet?The flex form backless will work in a pinch but the carpet on the seats is much stiffer than the flex form. Flex form will stretch in every direction making it un-suitable for something like that. Although maybe you could glue some backing to it and make it work. It's worth a try for sure. I've been able to re-use the carpet section from most of the seats I've done with the carpet back. Obviously that's not always possible.

I did get some black non stretchy backless a while ago from DLT or Midwest Fabrics I'm not sure which, but it was a random cut and not a stock item. it is very similar to the backless German Velour from GAHH. That may be worth a try. -

SharpiesI use china markers to mark foam. I will never use sharpie on the foam for my projects. It will bleed! ... Okay so maybe you'll get lucky and it won't bleed through your sew foam ... but maybe it will. Why take the chance. Just use a china marker, crayon, or some other type of washable marker.

If I had employees I would ban sharpies, and ball point pen for all but the secretary. Violation of the ban would result in 2 week suspension minimum.

Black china markers

colored china markers -

Going Mobile?I'm a one man show here. I absolutely will not do work outside of my shop. Actually I won't go to a customers location for an estimate. Its mainly due to how much time there is in the day. I can barely keep up with the work I have now, much less try to work out of some unknown space. If I had the desire to deal with employees, I think I'd actually enjoy doing some on location work, and let the employees deal with the day to day stuff.

Look at what others in your area charge, plumber, electrician, HVAC, your time is worth more than any of those guys. The last time I had to call a plumber 10 years ago or so, It was $90.00 minimum service charge weather he does any work or not. It seems high but when you consider time, fuel, wear and tear on your vehicle. $90 seems average, maybe even on the low end.This requires an additional "service" charge — Fred Mattson

For sure raise your labor rate, $300 for 14 hrs. that's only 21.43 per hour. Compare that to any other skilled labor rate in your area. My starting/minimum price for a bow style headliner is 600 and that's at my shop. Obviously what can you charge depends on cost of living in your area and your reputation. I went 1 step forward and 2 back for so long, because I wasn't charging enough. -

Patterning techniquesSorry I have not done that yet. I'll see if I can work that in soon, I've just been super busy.

-

Average amount of hours it should be takingthere are too many variables, there are so many different types of seats , headliners etc... Some are fairly easy, others are very complex. — Mike Goldring

For me 16 hours on a single bucket seat is flying... I can have 3 to 6 hours just making the pattern depending how complex the seat is. But almost everything I do is custom, there is no such thing as using a previous pattern. On occasion I'll be able to cut apart the existing cover and use that as a pattern, but that's rare.

I think the time scale thing is a bit pointless really unless your talking about the same make/model of seat, door card etc. — Gareth Judd

There was a time estimate list posted here on THR for boat seats/interior. That list for me is pointless, due to the "custom" type of work I do. I don't recall what any of the times were on that list. But if I had followed that for estimates I would have 30 hours or so that I wouldn't have charged for. I had around 10 hours just marking & sewing double diamonds on the last set of boat seats I did.

Once you have done 4 or 5 complete interiors on Tri 5 Chevy's you'll be able to more accurately estimate times on Tri 5 Chevy's. There is not a big difference from a 55 to a 57. Those same times won't work for a 39 Packard, or a 70 Challanger. Just too many variables from one to the next.

Unless you only sell and install Alea leather kits, don't bother trying to get an estimate sheet built up for something as general as a bucket seat. Every job is different, and everyone has a different skill set. Experience is the only way to figure out the average hours for you. Don't give out round about estimates over the phone. Make sure you see what your estimating before you say anything about price. I've been in the business for 18 years and I would have to say that estimating over the phone was my biggest mistake. -

I’d love to see everyone’s custom door armrestsFirst thermo formed arms, Went through a lot of ABS to get results with my crude setup. But I learned a lot in the end.

Andy Laird

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring