-

Thread problems (and stitch)Did you ever get an answer or feedback. I used to have this happen ever once in awhile. It was normally because of the thread…. I personally sprayed the spool and machine components the thread ran thru with silicon spray. Plus make sure the eyelet on the thread stand is exactly above the center of spool.

-

Retail pricing and shipping costsIf you don’t include shipping on your invoices it can be wrote off as a tax deduction. At least in Maryland any ways. So I personally just leave it off the invoice and write it off. One less thing being taxed. And one less thing for the customer to question

-

Silver pen use@Lee Thiel you also have to beware which type of dawn dish soap you use as I found this out recently with a fancy Sunbrella Vinyl.

I use Dawn all the time but forgot I had the extra strength degreaser Dawn… After cleaning the vinyl I steamed it with my Jiffy… and I think the heat made the chemicals in the dawn react to the vinyl taking the protective layer off. It made the Sunbrella Vinyl lighter in color wherever the heaviest residue was left. Looked like I sprayed it and left it to dry. Let’s just say I was pissed. -

Polyurethane Faux Leather

Anything on furniture/RVs/Boats that’s like a Faux leather are inferior materials… I’ve seen the same thing on early 2000’s SeaRay boat dinettes. I’ve replaced plenty of them.

Best Faux leather I’ve used is Ultra Leather. I was surprised how it held up on a customer’s, live aboard boat with 3 dogs. It’s actually pretty hard to scratch/damage almost like Sunbrella canvas in a vinyl sense. -

Landau foam/Custom panels@Zakk Easley@Jesse carr

The reason you shouldn’t spray the open cell foam is because the glue when in liquid form seeps into the foam. Then once you lay your material on and it drys… any pressure to the foam after curing pushes any air bubble out of the pores/ open cells making an indentation. This normally only happens on anything with a solid back like a panel.

Other wise I’ve never had an issue…

Best bet is to glue to material and cure.

I’ve also learned contact cement is an amazing thing if you know when and how to use it in different situations.

For example I’d never spray glue on Ultra leather to hold it down to Scrim/sew foam… even if it was a light coating on one side. -

Forgot to use poly thread on a boat seat but none of the thread is exposedSungaurd Bonded Polyester UV, Serabond bonded polyester (Amann), Eddington Bonded Polyester. Dabond…

Then theres Solarfix, Tenera Gore-Tex….

I do a lot of marine upholstery and canvas. I always use Bonded UVR Polyester thread… size 92 for upholstery and size 138 for canvas. If the customer is paying extra I get the Tenera. But I love the job security of using Bonded polyester when the customer comes back 5-10+yrs later for a restitch on canvas. Gives me a chance to up-sell new canvas or something else. I never have to do restitching on upholstery and I’d prolly never do it.. just replace. -

Tools!

I plan to make a couple more since some disappeared and the padding is shot. I had 6, 12, 24 and 36” -

Welt shrinking and causing some waviness in vinyl boat cushions.I’ve learned depending on material (fabric/vinyl) pay attention to sewing on the Bias of that material. Sometimes you have to feed the welt in and other times just letting the machine do the work while paying attention to stretch and pull.

Also like above stated make sure you have the right size feet for welt. Then also adjust pressure feet pressure and thread tension. If you notice you’re sewing with a 6mm stitch length and it’s performing a smaller stitch length then it’s gathering and causing the issue. -

Foam Cutters@Lee Bunce I did a review on one of the cheaper foam saws from sailrite. I just updated it. The saw is okay but the motor has held up to my abuse the last 3 years.

-

Sailrite Foam Saw ReviewSailrite Foam Saw is still kicking. The dowel holding the 2 blades in place by the base is worn out but I’ve made do.

I got tired of the meat cutters, razor blade, etc and wanted something to help cut down on time. So I finally thru together an old table saw, couple parts and now I have a pretty universal foam saw.

-

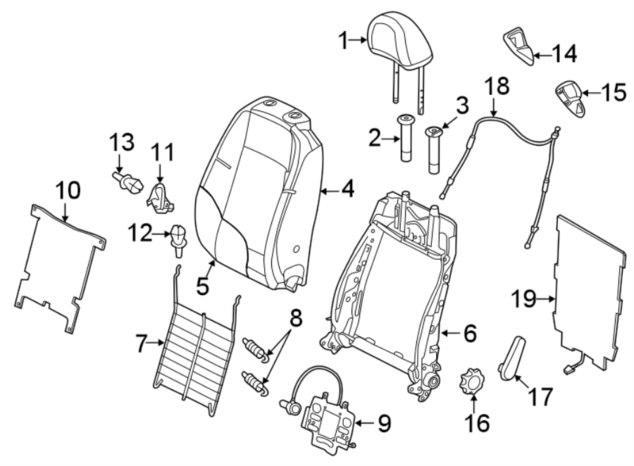

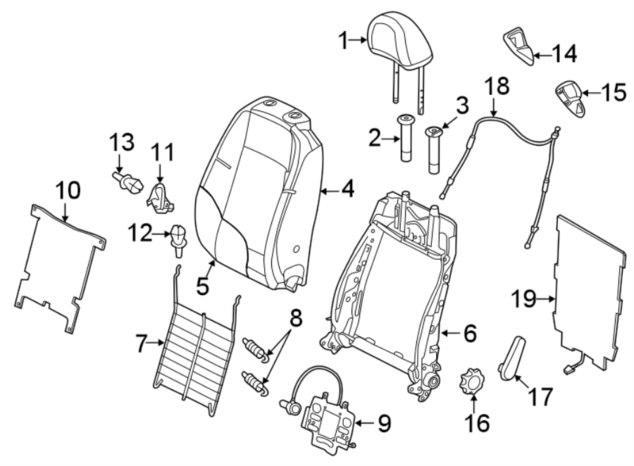

2017 beetle seats[reply="Dan Stewart;d760"

I’ve always seen them attached to seat foam bun and not integrated into the covers. Found some pics… hopefully they help.

-

1969 Camaro Design SketchesI’ll have to agree. Your rendering with the software you’re using looks great. I think It’ll turn out the way you’ve envisioned for sure.

For future inspiration I always look to my environment…

Plus the lines and shapes on said project. You’d be surprised what original ideas you can come up with…

-

Patterning techniquesHonestly you’d be surprised what you can find from a warehouse supplying sign shops in your area. I have one 2 miles away I worked at years ago before getting into upholstery. They use all kinds of products adhesive backed we could use for patterning on different applications. I buy a lot of PVC foam board and HDPE King Starboard for marine applications thru this warehouse.

-

EZmatch Swatch Scanner (DLT- now acquired by Keyston Bro’s)Thanks for the feed back everyone. It is a great thought and it seems I’ll just stick to matching by eye. Hopefully this helps someone else with their decision too

-

Looking for Bosch Foam Saw

Have you or anyone you’re aware of on the forum tested these Consew foam saws?? I’ve been seeing a lot more of them just rebranded. Would love to know.

Industry Tool Review Category, would be awesome too. No one likes buying overpriced junk if it’s avoidable.

Thanks in advance -

Looking for Bosch Foam Saw@Al Decker

@Chris Vining

Pictures didn’t show up but if you search in the regular forum for “Sailrite Foam Saw Review” you find it

Alright I don’t make a lot of post because I can never find the time but I felt this was worthy of a review for future purchasers of foam saws

Couple key points about the saw (might be a little lengthy):

Semi sturdy but cheaply made at the same time. Dropped once and the dowel pin for the stationary blade fell out. Replaced the dowel pin correctly and it had a lot of vibrations in the motor but still worked.

Stationary blade has one dowel pin at the bottom and nothing else at top of shaft to secure blade. If shaft isn’t machined correctly or wears prematurely due to inferior metals the blade slides out interfering with smooth cutting. Had the saw replaced and second one had same issues but can say customer service was very helpful. Not worth 3rd time because of design flaw.

Saw shaft is about 1” not including blades which makes sharp corners and small maneuvers difficult for smooth cuts.

Couple visual features making the saw more appealing but have no fucntion are the dust collector on the back of the saw. Plus the oscillating switch that has no purpose but looks.

These saws replica the other saws 4skjpxs866uxkase.jpeg

t7h7fkamaeq0kwrq.jpeg

dfkeohqw6twemg38.jpeg

s7j6ybff3lt0mnk3.jpeg

xqndekbmkta3eqpb.jpegon the market like the accucutter 350 and 500. Whether they’re the same quality I couldn’t say until someone does a review. Ever since the Bosch was discontinued I fell someone should buy up the patent and reproduce them. Was the best saw on the market in my opinion. 3kk9n2qmd27df3q4.jpeg

I have cyeg2waiwfxt1nrm.jpeg

a video showing the oscillating feature for show but can’t get it to upload. Also forgot to mention it has six speeds and the corner cut in the picture is on the lowest setting because of excess vibration.

Don’t get me wrong the saw works for 200 and does better then a meat carver but also has its flaws and I can say it won’t come close to a Bosch. -

Looking for Bosch Foam Saw@Al Decker Never seen the foam cutter you linked.

Hercules is a Harbor Freight brand so I assume they invested more in the looks then design “Chinese Made” with cheap materials. If you have any experience with the Hercules saw I’d love to hear your feedback along with other forum members.

I wrote a review on the blue saw linked above @Chris Vining. Sailrite and multiple other company’s sell them just rebranded. Chinese junk ( surprising the Black & Decker motor has held up tho) I’ve owned 2 and second one was a replacement a week later. Both had same defects. There is a cordless one also. From experience tho they are all cheap knockoffs of the Accu Cutter 500 (dual moving blades) and the lower end Accu Cutter (single moving blade one stationary) Don’t have experience with Accu Cutter I’d love to see a review though.

I’ll try to link my review of the other saw -

Have you ever tried?Looked thru my photos and couldn't find any Sunbrella covered seats other then one I did years ago with wrinkles thru it. Learned a lot since then about Sunbrella. I might have misunderstood though. Were you interested in Automotive or Marine Seats covered in Sunbrella??

I would have no problem using sunbrella for an automotive application if it was a new foam job (Firm w/ minimal complex curves). Otherwise I'd never use it. I can say now its very durable for work applications in rear seats. Especially for hunters with dogs or other heavy use applications. I live in a big farming and hunting region. Eastern Shore Maryland -

Duplicating these diamondsThis can be accomplished either CNC or Handmade. http://www.relicateleather.com can do it custom or I think Alea Leather and Katskinz have premade kits.

Handmade... Its a puzzle sewing red stitching to vinyl/leather first. Mark your start and go from there moving in Up/Down/Diagonal pattern crossing lines and connecting corners. If CNC can do it without stopping so can we. Black Stitching should already be marked before starting red stitching. Once red top stitching is done add 1/2" sew foam before sewing black diamonds. This would look similar but im almost positive its a firm 1/2" sew foam with a V groove cut out 1/4" deep and 3/8" wide on both sides of black diamond stitch -

Have you ever tried?I do a lot of marine canvas and upholstery with Sunbrella. Yes anything with complex curves or contours will create wrinkles. If you have a heavy duty steamer like a Jiffy then a lot of wrinkles can be steamed out like a dream. Heads up incase you've never tried to steam Sunbrella.

-

PricingReally depends on Year, Make, Model, Materials being used and whether you're installing/removing or its dropped off and picked up--- Plus Area/ # of shops in said Area. I'd prefer dropped off for cheaper customers that way I'm not liable for unforeseen issues with removal/ install. With that said....

150 + Materials x 2.... Reg Cab American Truck

250 + " ".... Crew Cab American Truck

300 + " ''.... American Sedan

Sunroof shade charge extra 50/75

These are all base prices for an idea, Didn't include variables

European I charge extra just because of the adhesive used/time for removal -

Cardboard tubes for material storage

Save these all the time for quality material storage. I do a lot of marine work and this is what the Glass comes in. Love the cardboard between the layers of glass for patterning certain jobs too. -

Raised door panels

Seen this late. Assuming it was closed cell foam sanded to shape. I love using PVC board, has a million different names but i use it all the time for marine applications that don't need heavy support/Structure. If it does need structure I'll use Starboard(marine use for 1/2", its expensive and heavy, but 1/4" with torch or Marine Heat shrink flame thrower can be molded in shapes like ABS plastic). You should think about using heavy duty magnets for inserts on the door panels. Not the initial fastner to door panel tho. -

How to make seams lay smoother@Michael Duncumb

Question is are you using original foam and and how much push back does it have. I see you're recovering using seats to sell to show you're craftmanship and quality. With that said judge the foam on age and use. Not sure how you pattern for new covers tho. Do you mark the old covers before removal and cut them up to pattern for NEW covers?? If so and using original foam I'd suck them in a little on seam allowance then steam foam after the covers are made. Again that depends on used foam quality and use. Or add sew foam 1/4, 3/8, 1/2 to covers and/or original foam to fill out covers. Again its all about how much you want to spend and sit one to shop your craftmanship.

As to the V cuts in seam allowance you almost always have to do it with Piping/Welt because of the 4 layers and certain radius.(this also depends on your seam allowance you use). Be careful tho, cut too big of V and too many with a tight cover they will show. Sometimes you just cut slits(reliefs) and trim you're seam allowance back. If you get good enough sewing you let the machine do the work and they will lay flat. Practice helps, just play with different ways

Justin L Rash

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring