-

Convertible topsI'm in Abbotsford B.C. I do convertible tops. 40+ years exp. Where are you located in BC?

-

Prepare yourself mentally for sewing.Took 2 weeks to find this. I remember this bit from (cough) 25 or (cough-cough) 30 years ago. Longer? M-m-may-be.

Anyways...I've always remembered it. These guys me laugh back then. Still do today.

No. I don't do furniture. Well, none that I am willing to admit to having done.

Someone should do an upholstery show such as this, based on automotive.

Jump to 3:42. Or watch the whole thing, just for the guy's back-n-forth banter.

-

Sewable plastic ???Check for an industrial plastic supplier in your area. The guys I use here have a huge selection. Similar to a lumberyard, but for plastic. Take a sample with you.

-

1987 Buick Regal limited headliner ????I wouldn't re-use that black factory deadener/insulation stuff. It's old & crispy. Near death.

Instead I'd put something like FatMat or DynaMat up there. Lots of other brands.

Run 3 strips about 8'-10" wide, evenly spaced,across the roof, side-side. Door opening-door opening.

Do this in front of that brace.

3 strips because odd numbered strips will cancel out any resonances. You could do 5 or 7 if you wanted. But they should be spaced the same distance apart as the width of the strips.

Going across the longest distance of the roof panel is like when you put your hand across a guitar's strings in order to stop them from...resonating!

So in behind that brace, once again running across the length, the strips would be running front-back. Different direction than the front.

A full covering of the deadener could be laid over top of all that too, but that's up to the customer & it's really not needed unless there's a higher end audio system being installed.

This is probably clear as mud. Lol!

Pix! I have pix!

Front-to-back. Because across the length.

Full cover.

-

Average amount of hours it should be takingFrom start to finish, this took 38 hours.

When I do custom stuff, I never repeat myself. Every one of these projects is a one-off.

If the customer has no ideas, no real plan, no basic renderings, & only gives me general parameters, ("Can you make it look like buckets with a center area for my small dog?") then I'm making it up as I go along. When the customer dropped off the interior, the only plan for the seat that had been agreed upon by the time he left the shop, was the colors.

Now if he had asked how long it was going to take, even after doing this stuff for (cough-cough!) 40 years, my honest answer would of been..."I don't know." I've used the techniques I did on this seat before & I will again, but I'll never repeat the design.

"Full interiors tend to be around the hundred hour mark." ~Keith Mayne~

That's about what I figure, too. But I've spent w-a-y more. It ll depends on what the customer wants along with how deep his pockets are compared to the shortness of his arms.

One of my interiors was in a Ridler Award Great-8 finalist (1997) I have over 300 hours into that one.

All those minute details add up! I had no idea that that was the length of time I was going to spend on that at the beginning of the project. Especially when the only guideline was "Create! ...GO!"

Yea, the owner was beginning to kinda freak out at the 200 hour mark, but hey...Great-8 finalist! In the end it was worth it. After the car was judged to the level it was & recognized as such, the $$$ didn't matter to the owner any more. His vision for the vehicle had been achieved.

People will remember the quality long after they've forgotten the price.

"Every job is different, and everyone has a different skill set. Experience is the only way to figure out the average hours for you." ~Andy Laird~

Yes! A project that takes me 40 hours may take someone else 30 or maybe 50. But are those guys that are doing it faster sacrificing the quality? You're only as good as your last job. It takes a long time to build a reputation. One half-assed job can cut that rep off at the knees.

"Don't give out round about estimates over the phone. Make sure you see what your estimating before you say anything about price. I've been in the business for 18 years and I would have to say that estimating over the phone was my biggest mistake." ~Andy Laird~

Exactly! That's like phoning a body-shop & asking..."How much to fix the dent in my vehicle?"

Well...is it a 'dent, or is it a 'DENT'? -

covering steering wheel air bagsCustomers tell me what they want.

I tell them what's possible.

Messing with steering wheel air-bags does not fall into the 'possible' category.

I wouldn't touch it.

I need to retain the ability to sleep at night. -

Dangerous things you foundIn a '65 Lincoln that had been brought up from the states, found a 9mm handgun in the trunk way down in behind the right rear wheel well.

Fully loaded with one in the chamber. The safety was NOT on!

But...it had been in there soo long that it just looked like a big chunk of rust. The inside of the barrel was a solid mass of rust. Corroded solid.

The car had even been inspected at the border when it was imported. The border guards don't usually miss stuff like that!

Other than the police here having them, a 9mm is not a common sight, up here in Canada. -

Cessna aircraft seat question..(quote) "The DER said it's an excellent question, but couldn't answer it." (unquote)

Lol! Like I said..."somewhat confusing."!

If the guys that are supposedly the interpreters of the regs can't decipher them in order to meet conformity, then how can they be strictly enforced?

Welcome to the world of aviation interior refurb! -

Cessna aircraft seat question..Great answer & info, there, Joe.

Didn't have a whole lot of time to go into a detailed response on my post.

I also have an AME ticket, (interiors) but my experience is certainly not anywhere near comparable with your background!

You're one of those guys us pups were looking to for clarification of the FARs when they got the better of us! Lol!

My favorite aspect of upholstery I've ever been involved in. -

Cessna aircraft seat question..Yikes! ...and can be somewhat confusing. But, non-compliance is not an option.

The aircraft's designated usage will dictate which of the F.A.R. specs that are required to be met

https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_25.853-1.pdf -

Glue potI've used these for years.

Nice for doing the suspended type headliners.that need to be glued to the body around the perimeter.

https://www.houseofcans.com/pint-heavy-duty-bristle-brush-detachable-handle-p-1093.html?cPath=124_5_32&houseofcans=uceotkn7recjnqbo6g50nppu15 -

Where to buy oem cloth for older vehicles? Detroit books?

Know exactly what you mean about 'that' company.

I've been looking for some factory seat fabric for a '91 454 SS. There's 2 types involved. Inserts then the rest.

Not down to the last resort of calling 'them', (yet) until I've exhausted all other possibilities.

With that said, anyone have a line on this or any connections that may be able to help?

Seems to me that it's not specific to the 454 SS, but a generic GM fabric across the line.

In red, of course.

The customer wants a complete recover of both so I'll be needing the appropriate amounts of yardage. -

Console hingesI've used the magnetic one-touch latch mechanisms which I first became aware of on glass stereo cabinet doors.

They work great for not only consoles but also for opening/closing panels in trunks.

Push closed till they 'click'. Push again for the 'click & they pop open.

Decent holding strength & totally hidden, too.

Lots of different sizes, in single or double door designs.

http://www.leevalley.com/en/hardware/page.aspx?p=56383&cat=3,41399 -

Vinyl DyesI use dyes as a last resort. Usually just to freshen up the original color of the material. Radical color changes are not a good idea.

A '60 Lincoln drop-top I did. The seats are leather & the door panels are vinyl. No problem acquiring the proper colors of leather, but finding matched vinyl was near impossible.

So I bought vinyls in colors as close as I could find, then had dyes color-matched to the leather & sprayed the roll stock before any pieces were cut out.

-

Thoughts on cutting foamI also worked on aircraft. (Biz Jets) & I loved using the pin saw. But the price is really hard to justify for a one man, 2 project-at-a-time shop.

Our wood shop guys made us a vacuum box to use with the saw. It held the foam upright via the vacuum, to do long angled/tapered cuts

As far as building one, I've considered a bandsaw with modified pulleys so as to be able utilize the pin wire that the Scandia machine uses. -

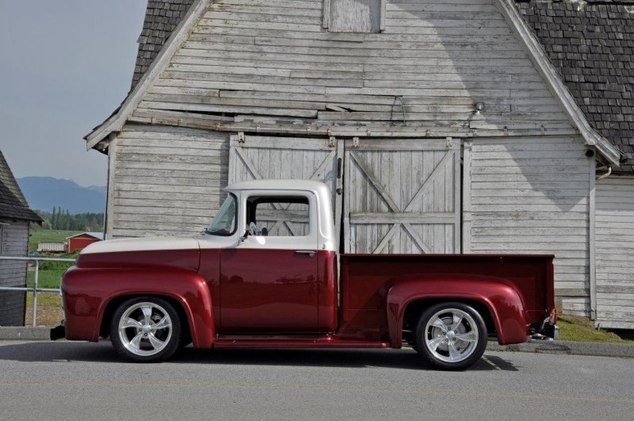

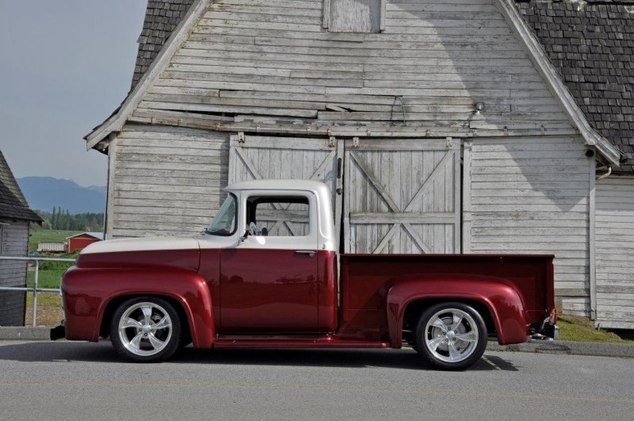

Show off your latest custom upholstery work.Not my latest, but it's a favorite. '56 F-100 with a 392 Hemi. GoodGuys award winner. (Puyallup. Wash.) People's choice. Judge's choice. Beast paint. Best interior. Best truck.

-

Catching dishonest shops red handed (Or not...)In one of the very first shops I worked in doing upholstery, the owner would always add at the bottom of the estimate...'Shop supplies...$xx.xx.'

It always seemed worked out to be just around that 10% margin. He explained that that was to cover things like hog-rings, glue, staples, etc, etc.

Never seemed right to me. A bit of a money grab. Padding the bill. Whatever.

I don't believe in that.

My view is that those 'supplies' are part & parcel of doing the job. If the estimate was done correctly, then there wouldn't have to be that caveat added on the end of the bill.

Al Decker

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring