-

Air bag seatsFirst of all I have to say that I can understand anyone who refuses to repair seats with airbags. Especially how you have to consider the legal situation and the jurisdiction in every country. In Germany - as far as I know - only the situation for the manufacturing industry is regulated. Not for the processed industry.

How we deal with it, I already told you here. The focus here was on giving an airbag additional cover, which I think is extremely dangerous.

However, I am of the opinion that the airbag will always function properly as long as the airbag seam is always the weakest point in the seat.

But I have a question about the Nissan label. Is the label "Do not resewn" attached to the airbag seam, or just sewn somewhere in the seat cover? Because when I translate the meaning for myself into German, I understand it that way:

The seat cover is patented. Copying is prohibited....

Or do I take this the wrong way? -

Recaro fabric@Astrid Helland

I made recaro seats out of the '70s two years ago that had this stuff too. The alternative fabric I bought from Döpper. I can find the article number for you on Monday.

-

Storing leather hides@Dean McConnell

We store our leather all rolled. In addition I have my own sample fan where also is noted which quantity is still available. Only the leather which I need for our series productions and black Nappa I store on a horse. From these hides I always buy 5 hides at once (discount). On the one hand, five hides are difficult to wrap on a roll and because I need them very often it is easier to handle them with a horse.

I never wanted to hang it up because I was always worried that the leather would fold and stretch unusually. Winding up the leather also has the advantage that it is protected from UV radiation. Depending on the storage location you should consider this - if it happens that the leather is in stock for several years. -

Porsche 964 roofHi Gareth. if the subject is still relevant to you. At least one of my suppliers indicated it as available in the online-shop. magenta costs 325€ extra. If you like I will ask if magenta is really still available. Here is the link to the softtop. You only have to choose the colour code 131A

-

Button machines for leather/ thick fabricDon't waste your time trying without a machine. As Hal said... if it's just a few buttons, go with the leather to a saddler who has a machine, or buy one. Anything else will only get you in a bad mood and with the quality of the Osborne you will certainly do nothing wrong. But meanwhile I also find good qualities in China at much lower prices. I have an old one myself, where I don't know the manufacturer. She doesn't work with a lever but with a turning spindle. This works very well and my tool supplier also has this type in their program. Unfortunately he is currently revising his website, so I can't post a link.

But also with the button machine you can get problems if the material is too thick. We already had the topic about making buttons some time ago. -

Foam cuttingThe band saw works fine. Especially if you attach a movable cutting table. Of course you need the appropriate space (which I unfortunately don't have missing). The band saw is especially unbeatable for thicker foam materials due to the precision. It has disadvantages when forming cushions (motorcycle seats or similar). The foam saws and grinding machines have the advantage again. I have 2 Bosch saws (31.5" and a 12" blade and belt grinder with a width of 0.4" and 0.8"). I get along very well with that... But 3-5 times a year I would like to have a band saw.

-

Going Mobile?Before I started with car saddlery I built pools. And at the beginning it was really hard for me to always work in the same place, because I missed the changing contacts and encounters with the people (in the training you have quite little contact to the customers) But meanwhile I hate it when I have to work outside the company...

Of course I also do work outside the company, but only if it can't be arranged otherwise. Here are a few examples:

- Adapting a hood on an 8 million $ Ferrari -> of course I don't want to have it in the workshop. Already because of the insurance this would be a nightmare. So I do it at the customer's home. But he pays me the time of the journey and a certain amount per distance.

- Assembly service / disassembly service of fitness cushions which I should cover -> Of course I do that. This is easy money. Finally you also pay the time of the driving and the driven distance.

- Working on unknown vehicles, oldtimers or other work where suddenly something happens that was not to be expected -> thats the reason why I HATE IT !!!!!!! Then you are miles away from your workshop, and have to improvise because you lack a tool, or you can't improvise anything in the foreign workshop. Our job is so full of surprises and new challenges... it is (from my point of view) always easier to work in your own shop. Because you can simply react better to any difficulties that arise. -

SharpiesDuring my education I once had the case that the lines I made with a marker on the foam were already visible after a few weeks. Whether this happened depends on many factors... similar to ballpoint pens. What color is the vinyl? how thick is the vinyl? Is the marker waterproof or not? What colour is the marker? I had the case that I used a black "cheap" marker and through the white vinyl only the red part of the black color came through. I have been using Edding Permanent Markers for years now. And I haven't had a problem since.

-

Shop Interior ColorsWhen I took over my company I also thought about the colour design for a long time. Because Nadeem is absolutely right that one counteracts the dirt with grey or dark colours. However, I was totally fed up with the dark colours. (For 12 years the lower parts of the walls were navy blue. And because the lighting was also very bad the whole workshop was a dark hole. Therefore, after the renaming of the company and the logo development, I have to follow the logo colors in the workshop and give the corporate identity even more profile. I admit that I exaggerated a bit with the base with the seam pattern. However, one should not underestimate what it does to the customer's subconscious. And I have often received the feedback: "you immediately notice that creative people work here" - without the customers having ever seen my work before.

And since I have taken over the company in all points in bad shape, I know how much the optical design of the workshop also contributes to the success of the company. Of course a bucket of paint doesn't turn you into a successful company, but the bucket can help. Here are a few pictures that illustrate what the bucket does for a difference.

-

2010 Camaro Alcantara headliner

I'll just post this here, because it fits the topic quite well. We recently had to make a headliner for a Jaguar Daimler V8 (X308), but the customer did not want to pay the extra price for removing the rear window, but asked us to cut the headliner into 2 parts. At the end I was really surprised how inconspicuous the edge above the headrests actually is. And I think it is - especially in terms of price - worth considering to offer it to the customer in this version as well. -

Automotive Upholestry Threads

-

Continuing EducationYes, there is a course over here... it's called upholsterer education with the specialization of vehicle upholstery. The "course" lasts 3 years and you are even paid for it... :sweat:

The money is not enough for rent and food and 5 times a year you drive 340 miles for 2 weeks each to school. There you will live in a dormitory which costs more in the 2 weeks than you earn per month. But at least the bad food is included in the price. :vomit:

When you have survived the three years and pass the final test, then you are a saddler here in Germany in the first place. Before that it is forbidden to open your own workshop.

But to be honest, after the 3 years you only got to know the basics about saddlery and you still haven't learned anything about running a workshop..... and even after almost 15 years I still learn more every day..... but at least it won't get boring. :sweat: :sweat: :sweat:

This was a quick introduction to the German autoupholster educations. :wink: -

2010 Camaro Alcantara headlinerI haven't made a Camaro headliner yet, but I can't imagine that the headliner can't pass through the big doors. Meanwhile I also did some models where the windshields supposedly had to be removed (VW Jetta notchback, Jaguar XJ etc) but they can also be removed without the removing the windshield. Often the problem is that the centre console is too high and the panels of the console have to be completely removed. Without a console you can tilt the headliner further and then fit diagonally through the door. I can't promise you this will work on the Camaro

-

Oldest shears you ever seen?That's an old pair of scissors for clipping sheep. I saw the scissors today at a colleague who found them in the barn that he converted into his workshop. Pretty impressive size... almost as long as my forearm. :gasp:

-

covering steering wheel air bagsFirst of all I have to say that I have the opinion that the customer does not decide what I have to do and how. He can say what he wants, but how and if I do this it is my decision alone. If someone wants me to sew a patch on the hole in the seat, I offer them 2 options: I replace the defective part or I sell him a needle and thread to make himself.... had the discussion today :roll:

But let's get back to the point:

Here you have to do a seminar to be allowed to work on airbags in general. Everything after that falls into a legal grey area. Because manufacturers of airbags may only sew with certified and regularly tested machines.

However, as upholsterer we are not considered as manufacturers in the real sense of the word because we are a processing industry. Maybe the translation alone is not quite understandable what I mean, because it really depends on the meaning of each word.....

In practice, my situation is as follows:

Airbag seams in covers: I sew these seams with an extremely thin thread. Even if the manufacturer (for example BMW used a thicker thread). I have not had an early open seam with the thread in the last 10 years and is also recommended by the thread manufacturer for this type of work. Of course, at the very beginning I didn't let myself take a few seats from the junkyard. :razz:

Steering wheels, door panels and dashboards: Here I only cover the parts without airbags. Unless they are covered and there is an airbag seam... then as described above.

As a matter of principle - and I think this is the only logical consequence - there must never be any additional resistance at the predetermined breaking points of the airbag. The additional resistance delays the inflation of the airbag. And this is a matter of milliseconds, on which a lot depends.

If you want to cover the plastic shell of the airbag now, you would have to cut open the predetermined breaking point of the airbag housing so that it no longer represents resistance. And the cover would then have to have an airbag seam at exactly this point. But that's just theoretical - I wouldn't do that.

My advice: Leave it alone, just because the customer wants a nice steering wheel I wouldn't put one foot in jail for a few dollars and a like on Facebook. (The last sentence is a German saying)

I hope you understand what I whant to discribe. :confused: -

Material clampsThen I'll start guessing. If you mean the same ones I use...

Here they called Fold-Back-Clip or Maul-Clamp over here. I bought them here. Sie haben sie in verschiedenen Größen. I use 0,75" , 1,25" and 2"

And since there are also great graduated discounts, I bought so many that I have enough until I retire. -

Listing material

Here you could buy it directly. But it is a little more expensive than with other suppliers...

Here are a few suppliers who have the above "tube strip" in stock.

Elsen & Hemer (Art.Nr: 0F0.053.583) in 22mm width

MAH has it in 19mm width. I also have to look for the article number.

Your sample is on the way! :wink: -

Show off your latest custom upholstery work.I like the jobs where the customer does not make any specifications and I can do and leave what I want. :grin:

-

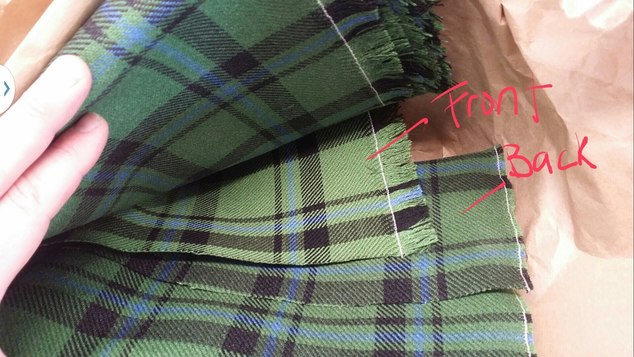

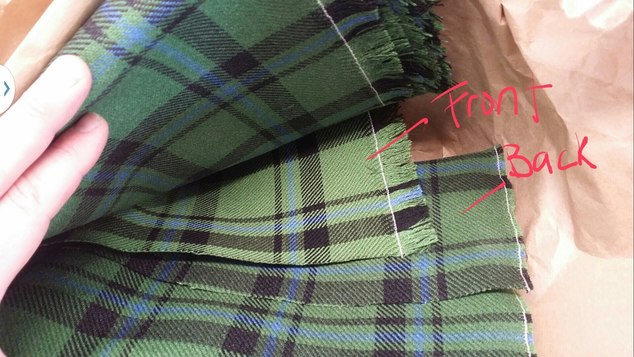

Make your own tartan fabricHere are some photos of the raw material and in processed condition. It is similar in quality to the Westfalia or VW Rabbit GTI tartan and is not as fine as the quality of the gullwing wool tartan.

-

Make your own tartan fabricI was looking for a tartan Karmann had used in some cars (Porsche 914, VW Scirocco I etc.). For various reasons I had to order the fabric more often. Once I ordered it from Auto Atlanta and once from someone I met in the VW scene. However, both materials were absolutely identical in structure and properties. Of course, none of the suppliers wanted to reveal where they got the material from. But with the information I got and a little research, I'm pretty sure they both have Scotsweb do the stuff.

About the quality, I can't say much yet, because the equipment is still not 2 months in use. The fabric is quite robust at first impression, but is not laminated. It is only a thin coating on the backside which reminds of transparent adhesive. -

Alternatives to AlcantaraAs Krunoslav had already said, Dinamica and Comfort would be an alternative. I don't like the microfibre of Dynamica as much as I do with Alcantara. The fibres are not as fine as in the Alcantra.

There are two great advantages to the Comfort of the MAH they have a very great deep black. In contrast, Alcantara's "deep black" still appears anthracite. (A photo for comparison: I combined black Bentley Nappa with the black Comfort) And this black is also available with a waterproof coating on the back.

Schauenburg also has a wide range of microfibre fabrics (I think it should be Dynamica)

-

Steaming LeatherI use an adhesive that can be activated with heat for dashboards and more complicated trim parts. For this I use sabaspray. I paint the cover and dashboard with it and let it dry so far that it hardly sticks at all. So I can easily position the cover and when I'm done, I take the hairdryer and heat up everything to glue it. Here I take a felt block to press the cover on.

-

Separating cloth from foamIf you don't have to reuse the cover, you can also use a warm lamp. I use the lamp most for glued leatherette covers. I heat it up to >140F°. You have to wait a while to get a deep heat. Then I carefully cut the covers in the middle with the scalpel and pull the cover outwards as if skinning. This usually works very well. Should a piece of foam get loose. Stop at this point and then start from the other side.

Jens Jesberg

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring